If you want to handle car bodywork repairs at home, you need the right tools for the job. Automotive experts say every home garage should include these main categories:

Hand tools like hammers, dollies, screwdrivers, and pliers

Specialty tools such as dent repair kits and panel repair tools

Diagnostic and electrical tools

Painting equipment and supplies

Power tools for tough tasks

Measuring and estimating tools

Glass repair tools

Shop supplies and personal protection

Having these tools in your home garage makes diy projects safer and much more effective. With the right setup, you can tackle car bodywork repair tools and get great results—even if you’re just starting out.

Garage Must Haves

When you set up your garage for car bodywork, you want to start with the right hand tools. These are the backbone of any repair project and make every job easier.

Hand Tools

Wrenches

You’ll use wrenches all the time in your garage. Open-end, box-end, and combination wrenches help you loosen and tighten nuts and bolts. For tight spots, crows foot wrench sets and extension wrenches come in handy. They let you reach fasteners in awkward places, so you don’t have to struggle or risk damaging parts. Look for wrenches made from chrome vanadium steel. This material resists rust and lasts longer, even with heavy use.

Screwdrivers

A good set of screwdrivers is a garage must have. You’ll need both flathead and Phillips types in several sizes. Magnetic tips make it easier to handle small screws, especially when you’re working in tight engine bays. Telescoping magnetic pickup tools can save the day if you drop a screw or bolt where your hands can’t reach.

Pliers

Pliers grip, twist, and cut wires or small parts. Needle-nose pliers work well for tight spaces. Slip-joint and locking pliers give you extra leverage. Keep a few types in your toolbox so you’re ready for any job.

Tip: Under-hood work lights are essential tools for car bodywork. They help you see clearly, even in poorly lit areas of your garage.

Socket Sets

A quality socket set is one of the top garage must haves. You’ll use it for almost every repair. When choosing a set, check for chrome vanadium or chrome molybdenum steel. These materials offer durability and resist corrosion. Six-point sockets grip fasteners better and prevent rounding, while twelve-point sockets are good for lighter tasks.

Deep Sockets

Deep sockets reach nuts on longer bolts, like those found in suspension or exhaust systems. Shallow sockets fit into tight spaces. Make sure your set includes both types.

Ratchet Wrenches

Ratchet wrenches speed up your work. They let you turn fasteners quickly without removing the tool after each turn. Always check if your socket set includes a ratchet wrench.

Breaker Bars

Breaker bars give you extra leverage for stubborn bolts. They’re longer than ratchets and help you break loose fasteners that won’t budge.

Note: Accessories like extension bars, adapters, and universal joints make your socket set more versatile. A sturdy carrying case keeps everything organized in your garage.

Torque Wrenches

Torque wrenches are essential tools for tightening bolts to the correct specification. Click-type torque wrenches are popular because they make a clear sound when you reach the right torque. This helps you avoid over-tightening, which can damage parts—especially softer metals like aluminum.

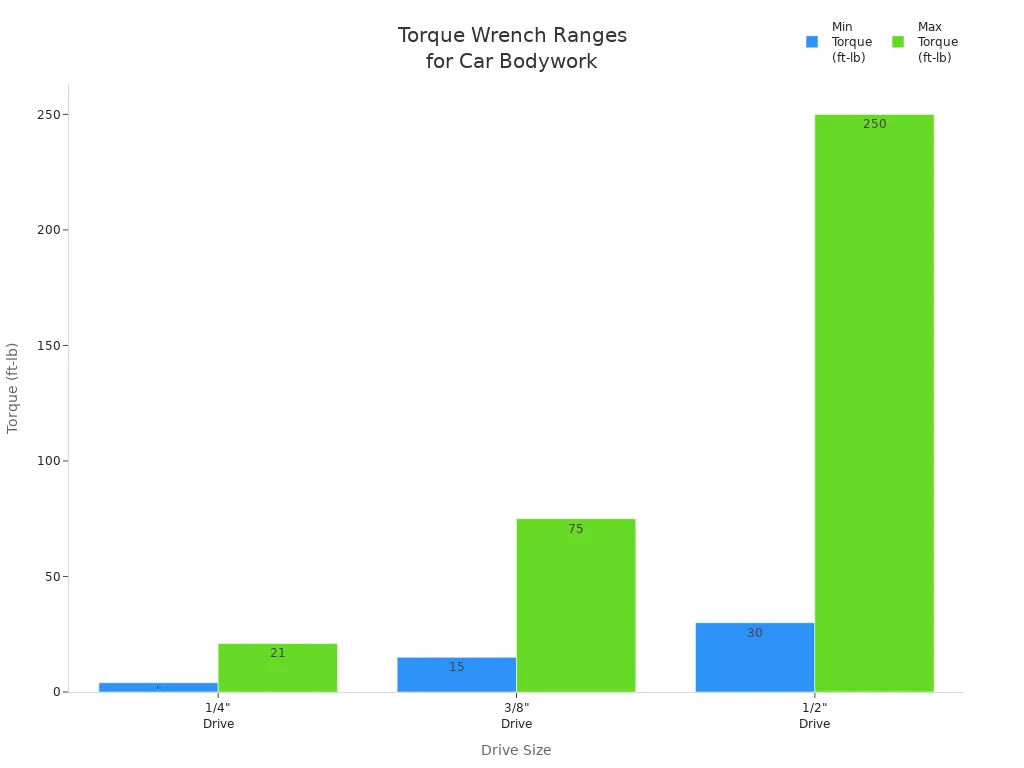

Torque Wrench Drive Size | Recommended Torque Range (ft-lb) | Typical Applications in Car Bodywork |

1/4" Drive | 4 - 21 | Small nuts and bolts, precise low torque tasks |

3/8" Drive | 15 - 75 | Most versatile; majority of vehicle nuts and bolts |

1/2" Drive | 30 - 250 | Larger nuts and bolts such as suspension, engine mounts, transmission mounts |

Choose a torque wrench that covers the torque range you need most. For best accuracy, pick one where your target torque falls in the middle of its range. After each use, reset it to the lowest setting to keep it calibrated.

Hammers

You can’t talk about garage must haves without mentioning hammers. These tools play a huge role in car bodywork repairs. You’ll find that different hammers serve different purposes, so having a variety in your garage makes every job easier and safer.

Here’s a quick look at some common hammers and how they help with car bodywork:

Hammer Type | Purpose and Contribution to Car Bodywork Repairs |

Welding Hammer with Brush | Cleans weld splatter and improves weld appearance, essential for fabrication tasks. |

Slide Hammer | Removes stuck parts like bearings and seals by pulling rather than pushing, aiding disassembly. |

Brass Hammer | Soft and anti-spark, ideal for delicate work around fragile components such as bearing races and fuel systems. |

Rubber Mallet | Prevents dents and dings when striking, useful for gently persuading stuck parts without damage. |

Ball Peen Hammer | Common light striking hammer for general use, providing controlled force for various mechanical tasks. |

Long Reach Picking Hammer | Reaches deep or hard-to-access areas, letting you work in tight spaces effectively. |

Door Skinning Hammer | Installs or removes door skins, with narrow heads to prevent damage to thin sheet metal. |

Straight Chisel-Back Hammer | Removes high spots and sharp edges, helps straighten and smooth metal precisely, equipped with shrinking face. |

Curved Chisel-Back Hammer | Shapes and stretches metal in complex curved areas like cowl panels and door skins. |

Shrinking Face Hammer | Compresses stretched metal to correct deformation from collision damage. |

Short Reach Picking Hammer | Fine-tunes seams, dimples, and small dents in hard-to-reach areas. |

You don’t need every hammer on this list to get started, but having a few key types in your garage will make a big difference. For most home garages, a ball peen hammer, a rubber mallet, and a slide hammer cover the basics. If you plan to do more advanced bodywork, consider adding a door skinning hammer or a shrinking face hammer.

Tip: Store your hammers on a wall rack or pegboard. This keeps your garage organized and makes it easy to grab the right tool when you need it.

Measuring Tools

Accurate measurements are the backbone of quality car bodywork. If you want your repairs to look professional, you need the right measuring tools in your garage. These tools help you check alignment, measure gaps, and ensure everything fits just right.

Tape Measures

A sturdy tape measure is one of the essential tools for any garage. You’ll use it to check panel sizes, measure gaps, and confirm part placement. Look for a tape measure with a wide, easy-to-read blade and a strong locking mechanism. Some tape measures even have magnetic tips, which help when you’re working alone.

Levels

Levels help you make sure panels, bumpers, and trim pieces sit straight. Even a small misalignment can stand out once you finish the repair. Basic bubble levels work well for most garage jobs. For more advanced work, you might want to try a digital level for extra accuracy.

Modern garages sometimes use advanced measuring systems, like electronic or 3D measuring tools. These systems use sensors and lasers to check vehicle dimensions and spot misalignments. Brands like Dent Fix and Mo-Clamp offer reliable options if you want to upgrade your setup. While these systems cost more, they help you achieve precise repairs and restore your car’s structure to factory specs.

Note: Keeping your measuring tools clean and stored in a dry spot will help them last longer and stay accurate.

Car Bodywork Repair Tools

Body Hammers & Dollies

When you start working with car bodywork repair tools, body hammers and dollies become your best friends. These tools help you fix dents, shape panels, and restore your car’s smooth lines. You don’t need a huge collection to get started. Most home garages do well with a small set—about three hammers and four dollies. Focus on quality and make sure the dollies match the curves of your car’s panels. A dolly with a crown just a bit higher than the panel works best. This helps you avoid flattening or stretching the metal.

Here’s what you’ll want in your starter set:

Bumping hammer: Great for starting dent repairs. It’s heavier and helps move metal quickly.

Finishing hammer: Lighter and perfect for final shaping and smoothing.

Pick hammer: Handy for raising low spots, but use it carefully to avoid making new dents.

Dollies: Choose shapes that fit your car’s contours. Place the dolly behind the panel and hammer from the front for most repairs.

Tip: Avoid shrinking hammers and dollies unless you know exactly how to use them. They can cause more harm than good if you’re not careful.

A professional 7-piece set usually covers all the basics. Look for durable steel construction and polished faces. These features help you get a smooth finish and make the tools last longer.

Sanding Tools

Sanding is a huge part of car bodywork. You need to remove old paint, smooth out repairs, and prep surfaces for primer and paint. The right sanding tools make this job much easier and help you get a flawless finish.

Sanding Blocks

Sanding blocks give you control and even pressure when you sand by hand. They help you avoid wavy surfaces and keep your work flat. Use sanding blocks for small areas, tight spots, or when you want to blend repairs into the rest of the panel. You can wrap sandpaper around the block and switch grits as needed. Start with medium grit (like 120-180) for shaping, then move to finer grits (up to 400-600) for finishing.

Power Sanders

Power sanders save you time and effort, especially on large panels. You’ll find several types, but orbital and dual-action (DA) sanders are the most popular for car bodywork repair tools. They give you a smooth, swirl-free finish and work well for both paint removal and surface prep.

Here are some common sanding tools and their uses:

Tool Type | Best For | Pro Tip |

Sanding Discs | Large areas, uniform finish | Use aluminum oxide for general sanding |

Flap Discs | Heavy-duty removal, grinding welds | Great for blending repairs |

Wire Wheels/Brushes | Removing thick paint, rust, seam sealer | Use in less precise areas |

Longboard Sandpaper | Smoothing large, flat surfaces | Avoid sanding marks by keeping surface clean |

Sanding Drums | Smoothing rough edges, heavy-duty removal | Use finishing drums for final smoothing |

Note: Always start with coarse grits for heavy removal, then move to finer grits for a smooth, paint-ready surface. Clean the panel before priming to help the paint stick.

Putty Knives & Spreaders

When you fill dents or scratches, you need putty knives and spreaders to apply body filler smoothly. Metal putty knives last a long time and clean up easily if you wipe them right after use. Plastic spreaders are also popular because you can peel off hardened filler, making them easy to reuse.

Spreaders help you:

You’ll want a few different sizes so you can handle both small touch-ups and larger repairs. Using the right spreader makes your work look professional and saves you time on sanding later.

Pro Tip: Clean your tools right after using body filler. This keeps them in good shape and ready for your next project.

Trim Removers

Trim removers are some of the most underrated car bodywork repair tools you can keep in your garage. When you need to take off door panels, moldings, or badges, these tools help you do it without scratching your paint or bending the trim. You want to avoid using metal screwdrivers or prying with your hands. That can lead to dents, chips, or even broken clips.

Here’s how you can use trim removers to protect your car’s finish:

Warm up the adhesive with a hairdryer or let the sun soften it. This makes the double-sided tape holding the trim much easier to remove.

Use plastic, non-marring trim tools or plastic razors. These let you gently pry the trim away without scratching the paint or denting the body panels.

Pull the trim slowly and evenly. Keep applying heat as you go. This helps prevent the trim from bending into the car and causing dents.

Take your time. Careful removal keeps your car’s finish and bodywork safe during repairs.

Removing trim before you start repairs or painting gives you a cleaner, more professional result. You won’t have to worry about masking lines showing through your new paint job. While some shops skip this step to save time, you’ll get better results if you do it right.

When you shop for trim removers, look for sets with different shapes and sizes. That way, you can handle everything from tight clips to wide moldings. Plastic tools are best because they won’t scratch or gouge your panels.

Paintless Dent Repair Kits

Paintless dent repair kits are a game-changer for anyone who wants to fix small dents at home. These kits let you pull out shallow dents from sheet metal without sanding, filling, or repainting. You save time and keep your car’s original finish.

Here’s what you should look for in a good kit:

Feature | Description |

Included Tools | Glue gun, glue sticks, slide hammer, bridge puller, spray bottle, button remover |

Dent Repair Capability | Pulls shallow dents from sheet metal without repainting |

Variety of Pull-tabs | Multiple sizes to fit different dent sizes |

Glue Gun Temperature | 120-248° Celsius (180-356° Fahrenheit) |

Glue Stick Material | Polyethylene |

Pull Button Material | Nylon |

Power Requirements | 120 VAC, 60 Hz, 80 watts, 24 in. cord length |

Storage | Blow-molded case for neat storage |

Usage Notes | Not recommended for plastic bumper covers and trim pieces |

Warranty | 1 Year |

You’ll also find kits with squeeze pullers, T-handles, and up to 24 different pull-tabs. Some kits include special glue sticks for aluminum panels and cleaning accessories for glue residue. If you live in a hot climate, try using ice to help the glue set faster.

Tip: Paintless dent repair kits work best on minor dents and dings. They won’t fix deep creases or damage on plastic parts.

These car bodywork repair tools are perfect for quick fixes and can save you a trip to the body shop.

Slide Hammers & Pullers

Slide hammers and pullers are must-have tools for anyone serious about car bodywork repair tools. When you face a stubborn dent that won’t pop out with a simple pull, a slide hammer gives you the extra force you need.

A slide hammer uses a heavy sliding weight on a long shaft. You attach the tool to the dented area, then slide the weight to create a strong pulling force. This action pulls the dented metal back into shape. You don’t have to remove interior panels or upholstery, which saves you time and effort.

You’ll find different attachments and hooks for these tools. That means you can tackle dents in tricky spots like door panels, fenders, and roofs. Most slide hammers are made from tough, drop-forged carbon steel, so they last a long time and handle tough jobs.

Slide hammers and pullers make dent repair more efficient and less invasive. You can fix dents without taking apart your car, and you get professional results right in your own garage.

If you want to expand your set of car bodywork repair tools, a quality slide hammer and puller kit is a smart investment.

Power Tools for the Garage

Cordless Drills

Cordless drills have become a must-have in any home garage. You’ll love how these power tools give you freedom to move around your car without dragging a cord behind you. No more searching for outlets or tripping over cables. You can reach tight spots under the hood or work outside if you need to. Modern cordless drills pack plenty of power, so you can drill holes, drive screws, or even use attachments for light sanding and polishing.

Here’s why cordless drills stand out:

You get better mobility and flexibility, which makes working on awkward areas much easier.

No cords mean fewer trip hazards and less risk of electrical accidents, especially if your garage gets damp.

Many models come with adjustable speed settings and built-in LED lights. These features help you work with more precision and see what you’re doing, even in dark corners.

Advances in battery technology mean you can work longer without stopping to recharge.

Lightweight designs and padded grips help you work longer without getting tired.

If you want to keep your workspace organized, cordless drills also help. Their compact size lets you store them easily and keep your garage tidy.

Impact Drivers

When you need to drive long screws or loosen stubborn bolts, impact drivers are the right tools for the job. These power tools deliver high torque in short bursts, making tough tasks feel easy. You’ll find them especially useful for removing rusted fasteners or assembling metal panels. Impact drivers are smaller than drills, so you can fit them into tight spaces. Many brands offer battery systems that work with both drills and impact drivers, so you can swap batteries and keep working without interruption.

Impact drivers are also great for:

Quick tire rotations or wheel changes

Installing or removing body panels

Working with self-tapping screws in metal

If you already have a cordless drill, adding an impact driver to your collection will make your garage setup even more versatile.

Angle Grinders

Angle grinders are some of the most versatile tools you can own for car bodywork. You can use them to cut metal panels, grind down welds, or remove rust and old paint. These tools spin at high speeds, so you need to follow safety steps every time you use one.

Here’s a quick safety checklist for angle grinders:

Always use the right disc for your task. Using the wrong disc can cause it to break or perform poorly.

Inspect your grinder and disc for cracks or damage before you start.

Secure your workpiece with clamps or a vice.

Hold the grinder with both hands for better control and stability.

Never remove the safety guard. It protects you from sparks and flying debris.

Wear safety glasses, gloves, and ear protection.

Keep your workspace clear of flammable materials.

Let the disc stop spinning before you set the tool down.

Work in a well-ventilated area to avoid breathing in dust or fumes.

Don’t force the grinder—let the disc do the work.

Tip: Air-powered tools like impact wrenches, air ratchets, and air sanders are also common in home garages. They run off an air compressor and can make many car bodywork jobs faster and easier.

With the right power tools and safety habits, you can handle almost any car bodywork project in your garage.

Heat Guns

Heat guns are some of the most versatile tools you can add to your garage. You might think of them as just hot air blowers, but they do much more than that. When you work on car bodywork, a heat gun can save you time and help you get professional results.

You can use a heat gun for many different tasks. Here are some of the most common ways you’ll use one in automotive repairs:

Soften old paint so you can scrape it off without damaging the metal underneath.

Shape and stretch vinyl wraps for a smooth, bubble-free finish.

Remove decals and stickers by loosening the adhesive, making them peel off cleanly.

Repair plastic parts by heating them until they become flexible enough to reshape or weld.

Pop out small dents by heating the metal, which makes it easier to work with.

Remove stubborn adhesives from trim, weather stripping, or badges without scratching the surface.

Thaw frozen locks, hinges, or seals during cold weather.

Activate adhesives or sealants for a stronger bond.

Dry repaired areas quickly before you apply primer or rust inhibitors.

Install window tint by helping the film conform to curved glass and removing bubbles.

You’ll find that a heat gun is one of those tools you reach for again and again. Most models let you adjust the temperature, so you can use them on everything from delicate vinyl to tough metal panels. Always keep safety in mind. Wear gloves and safety glasses, and never point the heat gun at yourself or flammable materials.

Tip: Let your heat gun cool down before you put it away. This keeps your workspace safe and helps your tools last longer.

Power Sanders

Power sanders make sanding jobs much faster and easier. If you’ve ever tried sanding a car panel by hand, you know how tiring it can get. With power sanders, you can smooth out repairs, remove old paint, and prep surfaces for primer in a fraction of the time.

There are a few types of power sanders you’ll see in home garages. Orbital sanders move in small circles and work well for general sanding. Dual-action (DA) sanders combine spinning and orbital motion, giving you a swirl-free finish. Belt sanders remove material quickly, but you need to be careful not to take off too much at once.

When you pick a sander, look for one with variable speed settings. This lets you control how aggressive the tool is, so you can switch from heavy removal to fine finishing. Dust collection features help keep your garage cleaner and protect your lungs from harmful particles.

You can use different grits of sandpaper with these tools. Start with a coarse grit to remove paint or shape filler, then switch to finer grits for a smooth, paint-ready surface. Power sanders are a must-have if you want your car bodywork to look professional.

Note: Always wear a dust mask and safety glasses when sanding. Clean your sander after each use to keep it running smoothly.

Safety and Support Equipment

When you work on your car, safety should always come first. The right support equipment and protective gear help you avoid injuries and make every job in your garage smoother. Let’s look at the essentials you need to keep your workspace safe and comfortable.

Jack & Jack Stands

You can’t do much under your car without a solid way to lift and support it. A hydraulic jack lets you raise your vehicle, but you should never trust a jack alone. Always use jack stands to hold the weight while you work. Most home garages use jack stands rated for 2, 3, or 6 tons per pair. These stands get tested to hold twice their rated capacity, so you can trust them when used correctly. Place them on a flat, solid surface and double-check that they lock securely before sliding under your car.

Tip: Wheel chocks add another layer of safety by stopping your car from rolling. Always set your parking brake and use chocks before lifting your vehicle.

Creepers & Mechanic Seats

Creepers and mechanic seats make working under or around your car much easier. A creeper lets you glide under your vehicle without crawling on the cold, hard floor. Most have padded surfaces and sturdy frames, so you stay comfortable during long repairs. Some even come with adjustable angles or built-in tool trays. Mechanic seats give you a place to sit while working on brakes or detailing wheels. Many have rolling wheels and storage trays for small parts. These features help you move around your garage and keep your tools close by.

Here’s what you get with quality creepers and seats:

Padded support for your back and knees

Durable frames that last for years

Smooth-rolling wheels for easy movement

Adjustable heights or angles for better access

Storage trays for bolts and small tools

You’ll notice less fatigue and more efficiency when you use these support tools.

Safety Gear

You face a lot of hazards in a garage, from flying debris to loud noises and chemical fumes. Wearing the right safety gear protects you from injuries and keeps you comfortable during tough jobs.

Respirators

Respirators protect your lungs from dust, paint fumes, and harmful chemicals. You need one when sanding, painting, or working with solvents. Choose a heavy-duty respirator for spray painting and make sure it fits snugly over your nose and mouth.

Safety Glasses

Safety glasses shield your eyes from sparks, metal shavings, and splashes. Always wear them when grinding, cutting, or using power tools. For extra protection, try a face shield during welding or when working with harsh chemicals.

Gloves

Gloves keep your hands safe from cuts, burns, and chemicals. Use thick, form-fitting gloves for most repairs. If you’re welding or working with hot parts, pick gloves made for high heat. For painting or handling solvents, use chemical-resistant gloves.

Note: Don’t forget about other safety basics. Keep your garage clean and organized to prevent slips and trips. Install fire extinguishers, smoke detectors, and carbon monoxide alarms. Store chemicals safely and inspect your equipment often.

A safe garage lets you focus on your projects and enjoy working on your car with confidence.

Organization in the Garage

Toolboxes & Cabinets

When you want your garage to feel organized and efficient, start with sturdy toolboxes and cabinets. These storage solutions keep your tools safe, easy to find, and ready for any project. You can choose from modular cabinets that fit your space or classic tool chests with drawers for every tool size. Many cabinets use steel or heavy-duty plastic, so they last for years, even in a busy home garage.

Here’s why toolboxes and cabinets make a difference:

Modular cabinets let you customize your storage. You can add shelves or drawers as your collection grows.

Adjustable shelving helps you store everything from small screwdrivers to bulky power tools.

Cabinets keep your workspace clean and professional. You’ll spend less time searching and more time working.

Lockable cabinets add safety by keeping hazardous materials and heavy tools out of reach.

Roller cabinets move with you, doubling as a mobile workbench.

Tip: Line your toolbox drawers with rubber mats. This stops your tools from sliding around and keeps them in good shape.

Wall Racks & Pegboards

If you want to free up floor space and keep your tools visible, wall racks and pegboards are your best friends. These systems turn empty walls into organized storage zones. You can hang everything from wrenches to power tools, making it easy to grab what you need.

Wall racks and pegboards come in many styles. Metal pegboards and slatwall panels hold up under heavy use. They resist moisture and grease, which is perfect for a garage. You can start small and add more panels or hooks as your needs change. This flexibility means your storage grows with your projects.

Here’s what makes wall racks and pegboards so effective:

They maximize vertical space, keeping your garage floor clear and safe.

You can create zones for different tool types or projects.

Hooks, bins, and shelves let you organize tools by size or frequency of use.

Magnetic strips and small containers help you store drill bits and other small metal items.

These systems look sharp, adding a professional touch to your home garage.

Note: Regularly return tools to their spots on the wall. This habit keeps your workspace tidy and saves time during repairs.

Portable Toolboxes

Sometimes you need to take your tools to another spot in your home or even outside. Portable toolboxes make this easy. They come in many sizes, from small hand-carry boxes to larger rolling carts. You can pack the essentials for a quick job or load up for a bigger project.

Portable toolboxes offer:

Strong, durable construction to handle heavy tools.

Multiple compartments for organizing small parts and hardware.

Easy transport, so you don’t waste time running back and forth to the garage.

A way to keep your most-used tools close, whether you’re working in the driveway or helping a neighbor.

If you want to keep your home garage organized, use a mix of fixed cabinets, wall storage, and portable toolboxes. This setup gives you the best of all worlds—order, flexibility, and convenience.

Labeling & Inventory

Keeping your garage organized goes beyond just having toolboxes and shelves. If you want to find your tools quickly and avoid losing expensive gear, you need a solid labeling and inventory system. This step saves you time and money, especially when your collection starts to grow.

Start by labeling every storage spot in your garage. You can use magnetic, adhesive, or metal labels. Metal labels last the longest, so they work well for high-use areas. If you want something high-tech, RFID labels let you track tools in real time. These are great for expensive or hard-to-replace items, but they cost more and work best for larger inventories.

A simple BIN system helps you know exactly where everything belongs. Here’s how it works:

Zone: Divide your garage into zones, like “Workbench,” “Wall Rack,” or “Cabinet A.”

Section: Break each zone into sections, such as “Drawer 1” or “Shelf 2.”

Position: Assign a position for each tool, like “Slot 3” or “Bin 5.”

So, a label might read “Workbench-Drawer1-Slot3.” This code tells you exactly where to return each tool. Keep your labeling style consistent across your garage. If you ever move things around, update your labels right away to avoid confusion.

Tip: Invest in high-quality labels and markers. Cheap ones fade or peel off, making your system useless.

For tracking, you can use a simple notebook, a spreadsheet, or inventory management software. Digital logs make it easy to check tools in and out, especially if you share your garage with family or friends. Some people engrave tools with unique ID numbers or attach RFID tags for extra security.

Here’s a quick checklist to keep your inventory system running smoothly:

Review and update your labels regularly.

Remove outdated or damaged labels.

Train everyone who uses the garage on your system.

Do routine audits to catch missing or misplaced tools.

Use durable tags or riveted labels for items that get heavy use.

A good labeling and inventory system keeps your garage running like a pro shop. You’ll spend less time searching and more time working on your projects.

Choosing Quality Tools

Durability

When you pick out tools for your garage, durability should be at the top of your list. You want tools that can handle tough jobs and last for years. Look for tools made from strong materials like chrome vanadium steel or forged carbon steel. These metals resist rust and don’t bend or break easily. If you see a tool with a lifetime warranty, that’s usually a good sign the manufacturer stands behind its quality.

Pay attention to the finish on your tools. A polished or coated surface helps prevent corrosion. Check the moving parts, like ratchets or pliers. They should feel smooth and solid, not loose or flimsy. If you drop a tool and it chips or cracks, it probably won’t last long in a busy garage.

Tip: Clean your tools after each use and store them in a dry place. This simple habit keeps them working like new.

Cost vs. Value

It’s tempting to grab the cheapest tools you can find, especially when you’re just starting out. But low-cost tools often wear out fast or break when you need them most. Instead, think about value. A quality tool might cost more up front, but it saves you money over time because you won’t have to replace it as often.

Here’s a quick way to compare cost and value:

Feature | Cheap Tools | Quality Tools |

Price | Low | Higher |

Lifespan | Short | Long |

Performance | Inconsistent | Reliable |

Warranty | Rare | Common (Lifetime) |

Safety | Can be risky | Built for safety |

You don’t have to buy the most expensive brand every time. Focus on tools you’ll use often, like wrenches, hammers, and sanders. Spend a little more on these, and you’ll notice the difference right away. For tools you use less often, mid-range options usually work fine.

Remember: Good tools make your work easier, safer, and more enjoyable.

Where to Buy

Finding a trusted supplier makes a big difference when you’re building your garage tool collection. You want a place that offers a wide selection, fair prices, and brands you recognize. Auto Body Toolmart stands out as a top choice for high-quality car bodywork repair tools. They’ve served the automotive industry for over 30 years and carry well-known brands like SATA, DeVilbiss, Ingersoll Rand, 3M, and Chicago Pneumatic. You’ll also find their in-house Champ Products line, which is made in the USA and known for its superior quality.

Shopping at a reputable supplier means you get genuine products, solid warranties, and expert advice if you need help choosing the right tool. You can also check out local hardware stores or specialty auto parts shops, but always look for trusted brands and good customer reviews.

Pro Tip: Stick with suppliers who have a long track record and offer support after your purchase. This gives you peace of mind and helps you get the most from your investment.

Having the right car bodywork repair tools in your garage makes every project safer and easier. You gain confidence when you know where your tools are and how to use them. Take a look at your current setup. See what you can improve or add.

Ready to tackle your next repair? Start building your dream garage tool collection today! ��️

FAQ

What are the first tools I should buy for car bodywork at home?

Start with a basic set: wrenches, screwdrivers, pliers, a hammer, a socket set, and a tape measure. These tools help you handle most simple repairs and upgrades. You can add more specialized tools as you gain experience.

Can I repair dents without professional equipment?

Yes! You can use paintless dent repair kits for small dents. These kits include glue pullers and tabs. For larger dents, a slide hammer helps. Always follow the instructions and take your time for the best results.

How do I keep my garage tools organized?

Use toolboxes, wall racks, and pegboards. Label each spot so you know where everything goes. Portable toolboxes help if you work in different areas. A simple inventory list keeps you from losing track of your tools.

Do I need power tools for basic car bodywork?

You can do many jobs with hand tools. Power tools like drills and sanders make work faster and easier, especially for bigger projects. If you plan to do more repairs, invest in a cordless drill and a power sander.

How do I stay safe while working on my car?

Wear safety glasses, gloves, and a respirator. Use jack stands when lifting your car. Keep your workspace clean and well-lit. Always read tool instructions before you start. Safety gear protects you from injuries and accidents.

What should I look for when buying new tools?

Check for strong materials like chrome vanadium steel. Look for a comfortable grip and a solid warranty. Trusted brands usually last longer. Read reviews and ask for recommendations if you’re unsure.

Can I use household tools for car repairs?

Some household tools work for simple jobs, like screwdrivers or pliers. For most car bodywork, you need automotive tools designed for higher strength and precision. Using the right tool makes your work safer and more effective.

How often should I clean and maintain my tools?

Clean your tools after every use. Wipe off dirt and moisture to prevent rust. Store them in a dry place. Regular care keeps your tools working well and helps them last for years.