![Best LBF Torque Wrenches Reviewed and Compared for Professionals]()

Professionals seeking the best lbf torque wrenches in 2025 should consider leading brands such as CDI, Tekton, ACDelco, Precision Instruments, Snap-On, MAC, Harbor Freight, SVOPES, Norbar, FACOM, DeWALT, KNIPEX, STAHLWILLE, BETA, and HAZET. These wrenches deliver top-tier accuracy and durability. Each wrench offers specific features for demanding tasks. Selecting the right wrench depends on drive size, torque range, and overall precision. The right wrenches provide reliable performance and excellent value. Quality wrenches from reputable brands ensure every wrench meets strict professional standards. Choosing the best wrench means prioritizing performance, longevity, and ease of use.

Top lbf torque wrenches 2025

![Top lbf torque wrenches 2025]()

Quick Recommendations

Professionals in 2025 demand lbf torque wrenches that deliver unmatched accuracy, durability, and advanced features. The following models stand out as the top choices for demanding applications:

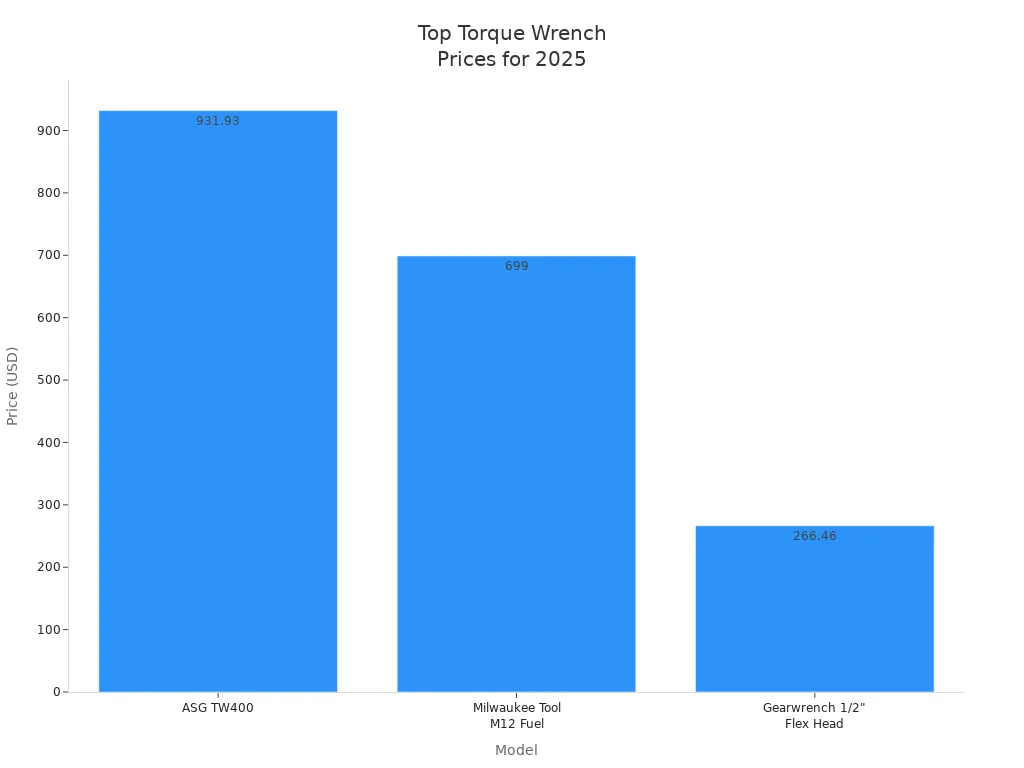

| Model | Torque Range (lbf.ft) | Max Measurement Deviation | Audio & Visual Feedback | Connectivity Features | Price (USD) |

| Atlas Copco STRwrench | 5.9 - 296 | ±0.5% | Yes | Connects with Atlas Copco torque software | Contact vendor |

| ASG TW400 | 11.0 - 110.0 | ±1% | Yes | PC connection via ASG software | 931.93 |

| Norbar NorTronic 1/2" | 24.33 - 243.3 | ±1% | Yes | Data feed to Norbar Torque Data System (TDS) | ~1700-1800 |

| Milwaukee Tool M12 Fuel | 12.5 - 150 | ±2% (clockwise), ±3% (ccw) | Yes | Compatible with Milwaukee One-Key app | 699 |

| Gearwrench 1/2" Flex Head | 25 - 250 | ±2% (clockwise), ±3% (ccw) | Yes | No advanced datalink mentioned | 266.46 |

These lbf torque wrenches lead the market in 2025. Atlas Copco STRwrench offers the highest precision at ±0.5% deviation and integrates seamlessly with proprietary software for data management. ASG TW400 and Norbar NorTronic provide robust connectivity and reliable accuracy, making them ideal for quality control in industrial settings. Milwaukee Tool M12 Fuel and Gearwrench 1/2" Flex Head deliver solid performance at more accessible price points, with user-friendly feedback systems and broad torque ranges.

![Bar chart comparing prices of top torque wrenches for professional use in 2025]()

Standout Features

Top-rated lbf torque wrenches for professionals share several essential features:

Precision and accuracy remain the foundation, with most models guaranteeing ±1% or better for critical torque applications.

Durability stands out, as these wrenches withstand thousands of tightening cycles without loss of calibration.

Ergonomic design ensures user comfort, with non-slip grips and clear, easy-to-read scales.

Advanced signaling systems, such as audio and visual alerts, notify users when the desired torque is reached, reducing the risk of over-tightening.

Digital displays and software connectivity enable real-time data logging, analysis, and quality control, supporting traceability in professional environments.

Multi-unit measurement scales (lbf.ft, N·m, in.lbf) provide versatility for various industries, including automotive, aerospace, and manufacturing.

Many models offer interchangeable heads and compact designs, allowing access to tight spaces and adaptability for different tasks.

Note: Professionals should select a wrench that matches their required torque range, desired feedback system, and connectivity needs. Models like the Atlas Copco STRwrench and Norbar NorTronic excel in environments where data management and traceability are critical, while Gearwrench and Milwaukee Tool M12 Fuel offer reliable performance for routine shop work.

Brands Compared

Premium Brands

Premium brands set the standard for professional lbf torque wrenches. These brands focus on precision, durability, and advanced features. Newstar Hardware stands out as a key recommendation for professionals seeking reliable brands. Their product range covers everything from low-torque wrenches for delicate tasks to high-capacity models for industrial use. Craftsman and DeWalt also maintain strong reputations. Craftsman, with over a century of experience, delivers wrenches known for comfort and reliability. DeWalt offers cordless impact wrenches with long battery life and sophisticated controls. These brands invest in innovation and quality, ensuring each wrench meets strict accuracy standards. Most premium wrenches feature ergonomic grips, clear scales, and advanced feedback systems. Professionals trust these brands for critical applications where precision matters most.

Tip: Premium brands often provide extended warranties and responsive customer support, adding value for professionals who rely on their wrenches daily.

Budget Brands

Budget brands appeal to professionals who need affordable wrenches without sacrificing essential performance. Pittsburgh and VEVOR lead this category. Pittsburgh wrenches, often manufactured overseas, offer reasonable quality and lifetime warranties. VEVOR wrenches impress users with their machined aluminum handles and ±3% accuracy, matching many premium models. User reviews highlight the durability and reliability of these budget wrenches, noting their readiness for heavy use. Many budget wrenches include adapters, extension rods, and sturdy cases, making them versatile for various tasks. The ergonomic design and clear markings support efficient operation. While budget brands may not match the innovation of premium brands, they deliver excellent value and performance for routine professional work.

Professionals report that budget wrenches like VEVOR perform reliably in demanding settings.

These wrenches offer features such as quick adjustment and user-friendly controls.

Budget brands balance affordability with acceptable accuracy, making them suitable for many professional environments.

The availability of lifetime warranties increases confidence in these wrenches.

Industrial Brands

Industrial brands specialize in heavy-duty wrenches designed for large-scale construction and engineering projects. Brands listed on GWY Inc. and Gedore focus on high-capacity torque wrenches that meet strict safety and compliance standards. Their product lines include manual, electric, pneumatic, and hydraulic wrenches capable of delivering torque levels above 300 ft.-lbs. These wrenches prevent structural damage and ensure reliability in demanding environments. Industrial brands emphasize accuracy, safety, and advanced features such as digital displays and power sources. Gedore demonstrates a broad product range, from the TORCOFIX K US 1/4" wrench for low-torque applications to the DMK series for high-torque needs. This spectrum covers torque requirements from 20 lbf.in to 550 lbf.ft, supporting diverse professional tasks.

| Model | Torque Range (lbf.ft) | Torque Range (lbf.in) |

| TORCOFIX K US 1/4" | 20 - 100 lbf.in | 20 - 100 lbf.in |

| DMK 200 | 150 lbf.ft | N/A |

| DMK 300 | 220 lbf.ft | N/A |

| DMK 400 | 300 lbf.ft | N/A |

| DMK 550 | 405 lbf.ft | N/A |

| DMK 750 | 550 lbf.ft | N/A |

Industrial brands deliver wrenches that meet the highest standards for accuracy and durability. Professionals choose these wrenches for projects where safety and compliance cannot be compromised.

Evaluation Criteria

Precision and Accuracy

Precision and accuracy form the foundation of any professional lbf torque wrench. High accuracy ensures that each fastener receives the correct amount of torque, preventing both under-tightening and over-tightening. Professionals rely on high precision tools to maintain safety and performance standards in automotive, aerospace, and industrial applications. The industry uses ISO 6789:2017 standards to define accuracy classes and tolerances for torque wrenches. These standards require calibration to be traceable to NIST and performed in controlled environments, often by ISO/IEC 17025 accredited laboratories.

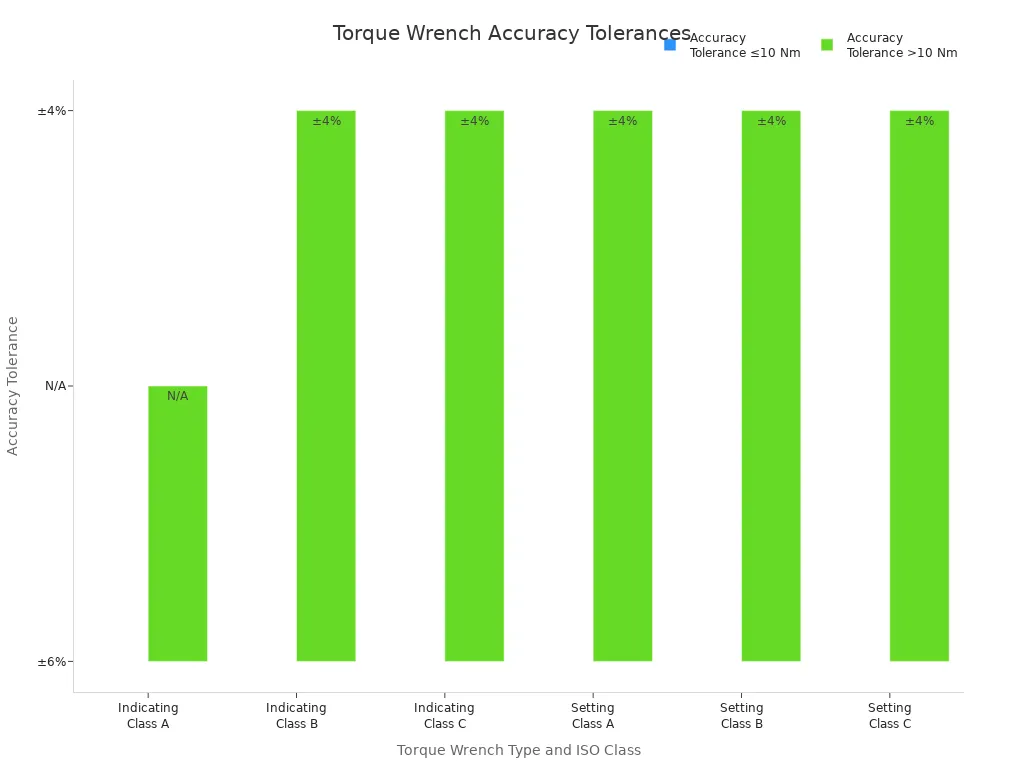

| Torque Wrench Type | ISO Class | Description | Accuracy Tolerance (≤10 Nm) | Accuracy Tolerance (>10 Nm) |

| Indicating Torque Tools | Class A | Wrench with torsion or flexing bar | ±6% | N/A |

| Indicating Torque Tools | Class B | Rigid body with indicator | ±6% | ±4% |

| Indicating Torque Tools | Class C | Rigid body with electronic measurement | ±6% | ±4% |

| Setting Torque Tools | Class A | Adjustable wrench with indicator | ±6% | ±4% |

| Setting Torque Tools | Class B | Fixed torque wrench | ±6% | ±4% |

| Setting Torque Tools | Class C | Adjustable wrench without indicator | ±6% | ±4% |

Calibration equipment includes torque transducers with ±1% accuracy, torque arms, and hydraulic benches. Proper calibration ensures that torque wrenches maintain high precision and meet ISO requirements over time. High accuracy is critical for professionals who demand consistent results. An easy to read torque scale further supports precision by reducing user error.

Note: Calibration intervals depend on usage, environment, and incidents such as drops or overloads. Regular calibration preserves both accuracy and tool quality.

![Bar chart comparing accuracy tolerances for torque wrench types and ISO classes]()

Torque Range

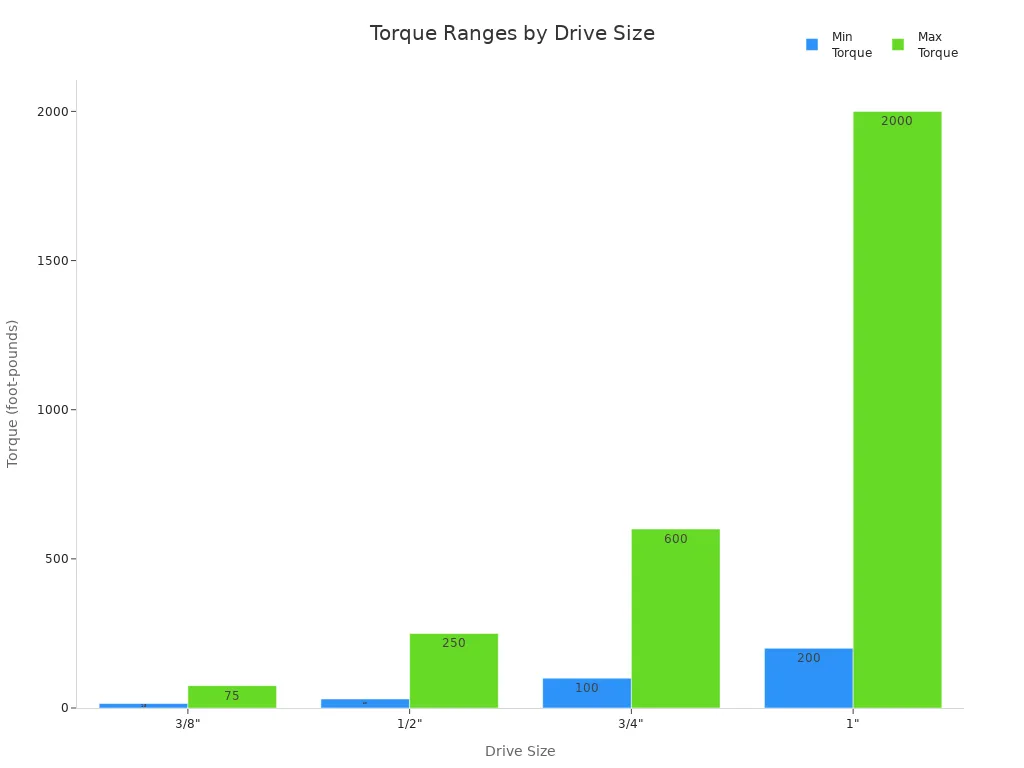

Selecting the correct torque range is essential for both safety and performance. Professionals must match the torque range of the wrench to the specific application. A wrench with a broad torque range offers flexibility for various tasks, from delicate fasteners to heavy-duty bolts. The drive size often determines the available torque range.

| Drive Size | Typical Torque Range (foot-pounds) | Common Applications |

| 3/8" | 15 - 75 | Light automotive tasks, motorcycles, spark plugs |

| 1/2" | 30 - 250 | General automotive work, lug nuts, engine components |

| 3/4" | 100 - 600+ | Heavy machinery, large trucks, industrial equipment |

| 1" | 200 - 2,000 | Heavy-duty industrial applications, large machinery |

A low torque range (4-18 foot-pounds) suits delicate work, while a mid-range (15-75 foot-pounds) covers most automotive needs. High range (75-185 foot-pounds and above) is necessary for industrial and heavy equipment. Professionals should always select a wrench with a torque scale that matches their most common tasks. An easy to read torque scale helps users set precise torque settings, reducing the risk of error.

![Bar chart comparing minimum and maximum torque ranges for different drive sizes]()

Build Quality

Exceptional build quality determines the lifespan and reliability of a torque wrench in demanding environments. Wrenches made from heat-treated alloy steel provide strength and wear resistance. Chrome plating adds rustproofing and simplifies cleaning, which is vital for maintaining tool quality during frequent use. A solid build, including an impact-resistant case, protects the wrench from damage during transport and storage.

High precision mechanical components, such as a 48-tooth ratchet, ensure smooth operation and consistent torque application. Exceptional build quality also means the wrench maintains its accuracy after repeated use. Customer feedback from professional settings confirms that high quality construction leads to tools that deliver reliable performance year after year. Good build quality reduces the risk of calibration drift and mechanical failure, supporting both safety and efficiency.

Tip: Professionals should always inspect the wrench for signs of wear and ensure that all torque settings function smoothly. Investing in exceptional build quality pays off in long-term durability and consistent results.

User-Friendliness

User-friendliness plays a crucial role in the selection of professional lbf torque wrenches. Professionals often work long hours, so ergonomic design features can make a significant difference in comfort and productivity. Manufacturers focus on several aspects to ensure their tools remain easy to use and reduce operator fatigue.

| Ergonomic Feature | Description and Benefit |

| Ergonomic handle design | Provides a comfortable grip, reducing hand fatigue during long use |

| Lightweight, well-balanced body | Enhances control and accuracy, especially in repetitive tasks |

| Large digital display | Prevents misreading torque values, supporting precise adjustments |

| Audible, visual, and tactile alerts | Warns users when preset torque is reached, preventing over-tightening |

| Reversible ratchet and bi-directional head | Allows efficient operation in both directions |

| Clear scale markings and dual graduation | Enables quick torque setting in both metric and imperial units |

| Soft, no-slip grip handle | Improves comfort and ensures secure handling |

| High-visibility LED screen | Facilitates easy mode selection and information access |

| Auto-off feature | Conserves battery life, reducing maintenance effort |

A torque wrench with a soft, no-slip grip handle and a lightweight, well-balanced body allows professionals to maintain accuracy throughout extended projects. Audible and tactile signals help prevent over-tightening, while a large digital display or high-visibility LED screen makes it simple to monitor torque settings. Dual graduation in both metric and imperial units supports diverse tasks across industries. These features combine to create a tool that is not only reliable but also easy to use for both experienced technicians and those new to torque wrenches.

Tip: Professionals should look for wrenches with ergonomic handles and clear displays to maximize comfort and minimize errors during repetitive work.

Price and Value

Price and value remain top considerations for professionals investing in lbf torque wrenches. The market in 2025 offers a wide range of options, from budget-friendly click-type models to advanced digital wrenches designed for aerospace and heavy machinery.

| Torque Wrench Model/Type | Intended Use/Grade | Price Range (USD) |

| Digital Torque Wrenches | Aerospace/Precision | $200 - $1,200 |

| Precision Instruments Split Beam | Aircraft/Heavy Machinery | Premium Model |

| Snap-on TECHWrench 3/8” | Auto Shops/Professional DIY | Mid-Range |

| Click-Type Torque Wrenches | Budget to Professional DIY | $50 - $400 |

Digital torque wrenches, often used in precision industries, typically cost between $200 and $1,200. Premium models, such as split beam wrenches for aircraft maintenance, can exceed $1,000. Mid-range options like the Snap-on TECHWrench offer professional features at a moderate price. Click-type wrenches provide reliable performance for routine tasks and remain accessible for most professionals.

When evaluating value, professionals should consider not only the initial purchase price but also factors such as warranty coverage, durability, and included features. A higher upfront investment in a premium wrench may result in lower long-term costs due to reduced calibration needs and extended tool life. Many brands, including Newstar Hardware, offer comprehensive support and warranties, further enhancing value for professionals who rely on their tools daily.

Note: Selecting a torque wrench that balances price, durability, and essential features ensures the best return on investment for professional users.

Reviews by Type

Click-Type Wrenches

Click-type wrenches remain a staple in professional toolkits. These wrenches deliver a tactile "click" when the preset torque is reached, helping users avoid over-tightening. Professionals value click-type wrenches for their reliability and straightforward operation. The most recommended models consistently offer long-term accuracy and robust construction.

Snap-On click-type wrenches receive high praise for durability and precision. One technician reported a Snap-On wrench maintained its accuracy after 35 years of use.

Craftsman click-type wrenches provide a strong balance between cost and quality. New models or properly calibrated used wrenches perform well in daily shop environments.

Milwaukee and Home Depot/Lowes brands also offer reliable click-type wrenches, but Snap-On and Craftsman stand out in professional reviews.

Calibration remains essential for maintaining accuracy, especially for used wrenches.

Click-type wrenches may lose reliability at low torque settings below 30 ft/lbs, as the click becomes harder to detect.

Professionals often choose adjustable torque wrenches for flexibility across different torque ranges. Preset torque wrenches suit repetitive tasks where a single torque value is required. For those seeking a trusted brand, Newstar Hardware offers a comprehensive selection of click-type wrenches designed for demanding applications.

Tip: Regular calibration ensures click-type wrenches maintain their accuracy and extend their service life.

Best Digital Torque Wrench

Digital torque wrench technology has advanced rapidly. The best digital torque wrench models now combine high accuracy, user-friendly interfaces, and advanced feedback systems. Professionals rely on digital torque wrench options for critical tasks that demand precise torque application and data traceability.

| Model | Accuracy Rating | Ease of Use Rating | Key Features and Notes |

| eTork EC3250 ½-Inch Drive Digital Torque Wrench | ±3% clockwise, ±6% counterclockwise | 5/5 | Audible click alert, easy dial adjustment even with gloves, converts between multiple torque units, locking knob to prevent accidental changes. |

| Summit Tools UltraPrecision Digital Torque Wrench | ±1% | 4.5/5 | LED lights as scale, buzzer alert, peak and tracking modes, comfortable rubber grip, requires batteries (not included). |

| Gearwrench 85077 ½-Inch Drive Electronic Torque Wrench | Not explicitly stated | 5/5 | Vibration, beep, and light alerts, clear display, multiple modes, difficult to set torque quickly. |

Digital torque wrench models like eTork EC3250 and Summit Tools UltraPrecision stand out for their accuracy and ease of use. These wrenches feature audible and visual alerts, ergonomic grips, and multi-unit measurement capabilities. Gearwrench 85077 offers vibration and light alerts, supporting efficient workflow in busy shops. Professionals select the best digital torque wrench for its ability to deliver consistent torque readings and advanced digital feedback.

Digital torque wrench options excel in environments where traceability and repeatability matter. Adjustable torque wrenches with digital displays allow quick changes to torque range settings. Preset torque wrenches with digital controls simplify repetitive tasks.

Split Beam Wrenches

Split beam wrenches offer a unique approach to torque application. These wrenches use a split beam mechanism to reduce internal friction, resulting in smoother operation and improved accuracy. Professionals prefer split beam wrenches for heavy-duty tasks and high torque range requirements.

Split beam wrenches maintain calibration longer than traditional click-type models. The design minimizes wear, making these wrenches ideal for industrial settings. Many split beam wrenches feature large, easy-to-read scales and robust construction. Technicians use split beam wrenches for applications where consistent torque delivery is critical.

Note: Split beam wrenches provide reliable performance across a wide torque range and require less frequent calibration than other types.

Dial Indicating Wrenches

Dial indicating wrenches provide professionals with a precise method for measuring torque. These tools feature a mechanical dial that displays the applied force in real time. Technicians use dial indicating wrenches for tasks that demand high accuracy and clear feedback. The dial moves as force is applied, allowing users to monitor torque and stop at the exact value required. This design reduces the risk of over-tightening and supports quality control in critical applications.

Many professionals prefer dial indicating wrenches for calibration work and laboratory settings. The analog dial offers instant feedback, which helps users maintain consistency across multiple fasteners. Unlike a digital torque wrench, the dial indicating wrench does not rely on batteries or electronic components. This makes it a reliable choice in environments where power sources are limited or where electromagnetic interference may affect digital readings.

Dial indicating wrenches excel in applications such as aerospace assembly, automotive engine work, and industrial maintenance. The clear scale markings and robust construction ensure durability and long-term accuracy. Some models include dual scales for both imperial and metric units, supporting international standards. Technicians appreciate the tactile feel and visual confirmation provided by the dial, which enhances confidence during precision tasks.

Brands like Newstar Hardware offer dial indicating wrenches designed for professional use. Their products feature hardened steel bodies, shock-resistant dials, and ergonomic handles. These features contribute to user comfort and tool longevity. Professionals seeking alternatives to a digital torque wrench often select dial indicating models for their reliability and ease of calibration.

Tip: Regular inspection and calibration of dial indicating wrenches ensure continued accuracy. Technicians should check for dial alignment and smooth needle movement before each use.

Deflecting Beam Wrenches

Deflecting beam wrenches stand out for their simplicity and reliability. Professional mechanics often choose these tools for their cost-effectiveness and accuracy. The design uses a beam that bends under load, with a pointer indicating the applied torque. This method eliminates the need for springs or complex mechanisms found in other wrenches.

Key advantages of deflecting beam lbf torque wrenches include:

Simpler design compared to other torque wrenches.

Lower cost, making them affordable for professional use.

Higher accuracy than many mechanical torque wrenches.

No spring relaxation issues, which can affect accuracy over time.

Minimal recalibration required, reducing maintenance needs.

These benefits make deflecting beam wrenches a popular choice for professionals who value reliability and precision. The absence of springs means the wrench maintains its accuracy even after extended use. Mechanics use deflecting beam wrenches for tasks ranging from automotive repairs to industrial assembly. The clear pointer and scale allow users to apply torque with confidence.

While digital torque wrench models offer advanced features, deflecting beam wrenches provide a straightforward solution for many professional settings. They do not require batteries or electronic calibration, which simplifies maintenance. Technicians appreciate the consistent performance and low ownership costs associated with these tools.

Some brands, such as Newstar Hardware, manufacture deflecting beam wrenches with hardened steel beams and easy-to-read scales. These products deliver long-lasting accuracy and withstand harsh working conditions. Professionals who need a dependable alternative to a digital torque wrench often select deflecting beam models for their proven track record.

Note: Deflecting beam wrenches require users to read the scale carefully during use. Proper technique ensures accurate torque application and prevents fastener damage.

Detailed Model Reviews

Newstar Hardware

Specs

| Specification | Details / Examples |

| Accuracy | ±3% |

| Torque Range | 0.42 N·m to 525 N·m (varies by model) |

| Torque Graduation | 0.02 to 0.2 N·m |

| Units Supported | lbf·in, lbf·ft, N·m |

| Type of Torque Wrench | Click type with interchangeable heads |

| Ergonomic Features | Resin grip, knurled metal handle, extension handle |

| Calibration Standards | ISO 6789:2017 compliant |

| Additional Features | Audible click, easy torque adjustment, clear scale |

Newstar Hardware offers a comprehensive range of torque wrenches designed for professional environments. Each wrench meets ISO 6789:2017 calibration standards. The models support both metric and American units, making them versatile for global use. The click-type mechanism ensures users receive a clear signal when the target torque is reached. Ergonomic handles and compact storage options enhance usability.

Pros

High precision with ±3% accuracy across the range.

Durable construction using high-quality materials.

Ergonomic design reduces hand fatigue during extended use.

Interchangeable heads allow adaptation to various tasks.

Audible and tactile feedback improves confidence in torque application.

Easy-to-read scale supports quick and accurate settings.

ISO 6789:2017 compliance ensures reliable calibration.

Excellent customer support and warranty through Newstar Hardware.

Unique Features

Newstar Hardware stands out for its commitment to precision and quality. The company provides a wide selection of click-type and adjustable torque wrenches, each featuring a robust build and user-friendly design. The extension handle allows for compact storage and easy transport. The clear click sound and tactile feedback help professionals avoid over-tightening. Newstar Hardware’s focus on compliance and customer service makes it a top choice for demanding professionals.

Professionals seeking a reliable, precise, and versatile torque solution consistently choose Newstar Hardware for their daily work.

Tekton Click

Specs

| Specification | Details / Examples |

| Accuracy | ±4% clockwise, ±6% counterclockwise |

| Torque Range | 10–150 ft-lb (varies by model) |

| Drive Size | 1/2 inch, 3/8 inch, 1/4 inch |

| Type of Torque Wrench | Click type |

| Calibration Standards | Pre-calibrated, NIST traceable |

| Ergonomic Features | Knurled handle, clear scale |

| Warranty | Lifetime warranty, fast replacement |

| Additional Features | Audible click, reversible ratchet head |

Tekton Click torque wrenches deliver reliable performance for automotive and industrial applications. The models come pre-calibrated and include a clear, easy-to-read scale. The knurled handle provides a secure grip, and the reversible ratchet head increases versatility.

Pros

Consistent torque delivery with audible click feedback.

Durable construction and robust materials.

Lifetime warranty with efficient customer service (replacements in about 4 days).

User-friendly design suitable for both beginners and professionals.

Multiple drive sizes cover a wide range of applications.

Pre-calibrated for immediate use.

Cons

Slightly lower accuracy compared to premium brands.

Audible click may be less noticeable at lower torque settings.

Some users report the handle can feel slippery with oily hands.

Not as compact as some digital torque wrench models.

Unique Features

Tekton Click wrenches excel in warranty and customer support. The company’s lifetime warranty and rapid replacement process set it apart from competitors. The clear scale and audible click make it easy to achieve precise torque settings. Tekton’s focus on sturdy construction and user-friendly features appeals to professionals who need dependable tools for daily use.

Tekton’s combination of value, reliability, and customer service makes it a strong contender in the click-type torque wrench market.

ACDelco Digital

Specs

| Specification | Details / Examples |

| Accuracy | ±2% clockwise, ±3% counterclockwise |

| Torque Range | 4–99 ft-lb (varies by model) |

| Drive Size | 1/2 inch, 3/8 inch |

| Type of Torque Wrench | Digital |

| Calibration Standards | ISO 6789 certified, includes calibration certificate |

| Torque Graduation | 0.1 ft-lb increments |

| Ergonomic Features | Rubberized grip, large digital display |

| Additional Features | Buzzer alerts, LED indicator, memory storage |

ACDelco Digital torque wrenches provide high precision and advanced digital features. Each wrench comes calibrated to ISO 6789 standards and includes a certificate. The digital display shows real-time torque values, and the buzzer alerts users when the setpoint is reached.

Pros

High accuracy and precision, verified in laboratory calibration tests.

Digital display allows for easy monitoring of torque values.

Buzzer and LED alerts reduce the risk of over-tightening.

Memory storage for multiple torque settings.

Ergonomic grip enhances comfort during prolonged use.

ISO 6789 certification ensures reliable calibration.

Cons

Requires batteries for operation.

Digital interface may have a learning curve for new users.

Slightly higher price point compared to mechanical wrenches.

Not as rugged as some analog models for heavy-duty environments.

Unique Features

ACDelco Digital torque wrenches stand out for their advanced digital interface and memory functions. The ability to store multiple torque settings streamlines repetitive tasks. The buzzer and LED indicators provide clear feedback, supporting precision in every application. The inclusion of a calibration certificate and compliance with ISO standards ensures professionals can trust the tool’s accuracy.

ACDelco Digital torque wrenches offer a blend of precision, digital convenience, and reliability, making them ideal for professionals who require advanced features and traceability.

Precision Instruments Split Beam

Specs

| Specification | Details / Examples |

| Accuracy | ±4% clockwise |

| Torque Range | 40–250 ft-lb (varies by model) |

| Drive Size | 3/8 inch, 1/2 inch |

| Type of Torque Wrench | Split beam |

| Calibration Standards | Factory calibrated, ISO 6789 compliant |

| Ergonomic Features | Long handle, easy-to-read scale, thumb adjustment |

| Additional Features | No need to reset to zero, audible/tactile feedback |

Precision Instruments Split Beam wrenches use a split beam mechanism to deliver consistent torque. The design reduces internal friction, which helps maintain accuracy over time. The wrench features a long handle for better leverage and a clear scale for easy torque setting. The thumb adjustment knob allows quick changes without extra tools.

Pros

Maintains calibration longer than many click-type wrenches.

Split beam design reduces wear and increases tool life.

Audible and tactile feedback signals when the set torque is reached.

No need to reset to zero after use, which saves time.

Large, easy-to-read scale supports precise torque adjustments.

Comfortable grip reduces hand fatigue during repetitive tasks.

ISO 6789 compliance ensures professional-grade accuracy.

Cons

Heavier than some digital or click-type torque wrenches.

Bulkier handle may limit access in tight spaces.

Not as versatile for very low torque applications.

Higher price point compared to basic click-type models.

Unique Features

Precision Instruments Split Beam wrenches stand out for their durability and low maintenance. The split beam mechanism resists calibration drift, making these tools ideal for professionals who need reliable torque application day after day. The wrench does not require resetting to zero, which prevents spring fatigue and extends tool life. The audible and tactile feedback helps users apply the correct torque every time. Many technicians choose this model for heavy-duty automotive and industrial work.

Tip: For professionals who want a long-lasting, low-maintenance torque solution, split beam wrenches from Precision Instruments offer a strong return on investment.

Snap-On

Specs

| Specification | Details / Examples |

| Accuracy | ±3% clockwise, ±6% counterclockwise |

| Torque Range | 5–250 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch |

| Type of Torque Wrench | Click-type, digital, split beam |

| Calibration Standards | Factory calibrated, NIST traceable |

| Ergonomic Features | Soft grip, compact head, clear scale |

| Additional Features | Dual scale, quick-release ratchet, serial number |

Snap-On torque wrenches set the industry standard for professional use. The company offers a wide range of models, including click-type, digital, and split beam designs. Each wrench comes factory calibrated and includes a serial number for traceability. The soft grip and compact head make the tool comfortable and easy to maneuver.

Pros

Exceptional build quality ensures long-term durability.

High accuracy meets the needs of critical torque applications.

Wide selection of drive sizes and torque ranges.

Dual scale (ft-lb and Nm) supports international work.

Quick-release ratchet head speeds up socket changes.

Serial number and calibration certificate provide traceability.

Excellent customer support and warranty services.

Cons

Premium price compared to most other brands.

Some models may feel heavy for extended use.

Digital models require batteries and occasional recalibration.

Availability may be limited to authorized dealers.

Unique Features

Snap-On torque wrenches feature robust construction and advanced engineering. The company’s click-type models deliver a distinct, reliable signal when the set torque is reached. Digital models offer real-time torque readings and memory storage for multiple settings. The quick-release ratchet and compact head improve workflow in busy shops. Snap-On’s reputation for quality and support makes these wrenches a top choice for professionals who demand the best.

Note: Many technicians report Snap-On torque wrenches maintain accuracy for decades, making them a trusted investment for any professional toolkit.

MAC

Specs

| Specification | Details / Examples |

| Accuracy | ±4% clockwise, ±6% counterclockwise |

| Torque Range | 10–250 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch |

| Type of Torque Wrench | Click-type, digital |

| Calibration Standards | Factory calibrated, ISO 6789 compliant |

| Ergonomic Features | Knurled handle, lightweight body |

| Additional Features | Reversible ratchet, easy torque adjustment |

MAC torque wrenches offer a balance of performance and value for professionals. The company produces both click-type and digital models, each designed for accuracy and ease of use. The knurled handle provides a secure grip, and the lightweight body reduces fatigue during long jobs.

Pros

Reliable torque delivery for automotive and industrial tasks.

Lightweight design improves comfort and control.

Reversible ratchet head increases versatility.

Easy-to-read scale supports quick torque settings.

Factory calibration ensures out-of-the-box accuracy.

Good customer service and warranty support.

Cons

Slightly lower accuracy than some premium brands.

Click may be less pronounced at lower torque settings.

Digital models require batteries and periodic recalibration.

Limited advanced features compared to high-end digital wrenches.

Unique Features

MAC torque wrenches stand out for their user-friendly design and solid construction. The reversible ratchet head allows for efficient work in both directions. The lightweight body and knurled handle make the tool comfortable for extended use. MAC’s focus on practical features and dependable performance appeals to professionals who need a trustworthy torque solution without the premium price tag.

Professionals who want a reliable, easy-to-use torque wrench for daily shop work often select MAC for its value and consistent results.

Harbor Freight

Specs

| Specification | Details / Examples |

| Accuracy | ±4% clockwise, ±6% counterclockwise |

| Torque Range | 20–150 ft-lb (varies by model) |

| Drive Size | 1/2 inch, 3/8 inch, 1/4 inch |

| Type of Torque Wrench | Click-type |

| Calibration Standards | Factory calibrated |

| Ergonomic Features | Knurled handle, clear scale, lightweight body |

| Warranty | Lifetime warranty (Pittsburgh brand) |

| Additional Features | Audible click, reversible ratchet head |

Harbor Freight, primarily through its Pittsburgh line, offers click-type torque wrenches that target professionals and budget-conscious users. These wrenches arrive factory-calibrated and ready for immediate use. The models feature a knurled handle for grip and a clear, easy-to-read scale.

Pros

Affordable pricing makes these wrenches accessible for most professionals.

Lifetime warranty provides peace of mind for frequent users.

Lightweight design supports extended use without fatigue.

Audible click feedback helps prevent over-tightening.

Multiple drive sizes cover a broad range of applications.

Readily available at retail locations and online.

Cons

Accuracy may drift faster than premium brands, especially with heavy use.

The audible click can be faint at lower torque settings.

Build quality does not match higher-end competitors.

Some users report inconsistent calibration out of the box.

Limited advanced features compared to digital or split beam models.

Unique Features

Harbor Freight stands out for its value proposition. The company delivers functional torque wrenches at a fraction of the price of premium brands. The lifetime warranty on Pittsburgh models appeals to professionals who need a backup or secondary tool. The simple, no-frills design ensures ease of use for both beginners and experienced technicians. While these wrenches may not offer advanced features, they provide reliable performance for routine automotive and mechanical tasks.

Note: Professionals often keep a Harbor Freight torque wrench as a backup or for less critical jobs, reserving premium tools for precision work.

SVOPES

Specs

| Specification | Details / Examples |

| Accuracy | ±3% clockwise, ±5% counterclockwise |

| Torque Range | 10–150 ft-lb (varies by model) |

| Drive Size | 1/2 inch, 3/8 inch |

| Type of Torque Wrench | Click-type, digital (select models) |

| Calibration Standards | ISO 6789 compliant |

| Ergonomic Features | Anti-slip handle, compact head |

| Additional Features | Audible click, dual scale, storage case |

SVOPES produces torque wrenches designed for both professional and advanced DIY users. The company offers click-type and digital models, each calibrated to ISO 6789 standards. The anti-slip handle and compact head improve control and access in tight spaces.

Pros

High accuracy supports critical torque applications.

ISO 6789 compliance ensures reliable calibration.

Dual scale (ft-lb and Nm) increases versatility.

Storage case protects the tool during transport.

Audible click and clear markings aid in precise torque application.

Competitive pricing for the feature set.

Cons

Limited availability in some regions.

Digital models require batteries and periodic recalibration.

Fewer drive size options compared to larger brands.

Customer support may not match established industry leaders.

Some users report the click is less pronounced at low torque.

Unique Features

SVOPES distinguishes itself with a focus on accuracy and ergonomic design. The anti-slip handle and compact head allow technicians to work comfortably in confined areas. Select digital models provide real-time torque readings and memory functions. The inclusion of a sturdy storage case adds value for professionals who travel between job sites. SVOPES offers a compelling option for those seeking precision without the premium price tag.

Tip: SVOPES torque wrenches suit professionals who need a reliable, accurate tool for daily use but want to avoid the cost of top-tier brands.

Norbar

Specs

| Specification | Details / Examples |

| Accuracy | ±1% clockwise, ±2% counterclockwise |

| Torque Range | 10–330 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch |

| Type of Torque Wrench | Click-type, digital, dial, and electronic |

| Calibration Standards | ISO 6789:2017, supplied with calibration certificate |

| Ergonomic Features | Soft grip, slim profile, large display (digital) |

| Additional Features | Data logging, wireless connectivity (digital), dual scale |

Norbar, a globally recognized brand, manufactures torque wrenches for industrial, automotive, and aerospace applications. The company offers a wide range of models, including advanced digital and electronic wrenches with wireless data transfer capabilities.

Pros

Exceptional accuracy meets the highest industry standards.

Wide selection of drive sizes and torque ranges.

Advanced digital models feature data logging and wireless connectivity.

Robust construction ensures long-term durability.

ISO 6789:2017 compliance with calibration certificate included.

Ergonomic design supports comfortable, extended use.

Cons

Premium pricing reflects advanced features and build quality.

Digital and electronic models require batteries and regular calibration.

Some models may be heavier than basic click-type wrenches.

Availability may be limited to authorized distributors.

Learning curve for advanced digital features.

Unique Features

Norbar stands out for its commitment to precision and innovation. The company’s digital and electronic torque wrenches offer wireless data transfer and comprehensive data logging, supporting traceability in regulated industries. The slim profile and soft grip enhance user comfort, while the broad product range covers nearly every professional need. Norbar’s adherence to ISO 6789:2017 and inclusion of calibration certificates provide confidence in every measurement.

Professionals in aerospace, manufacturing, and quality control rely on Norbar for critical torque applications where accuracy and traceability are non-negotiable.

FACOM

Specs

| Specification | Details / Examples |

| Accuracy | ±3% clockwise, ±6% counterclockwise |

| Torque Range | 10–340 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch |

| Type of Torque Wrench | Click-type, digital, dial |

| Calibration Standards | ISO 6789:2017, supplied with calibration certificate |

| Ergonomic Features | Bi-material handle, anti-slip grip |

| Additional Features | Quick-release ratchet, dual scale, compact head |

FACOM torque wrenches deliver robust performance for professionals in automotive, aerospace, and industrial sectors. The company offers a wide range of models, including click-type, digital, and dial indicating wrenches. Each wrench arrives calibrated to ISO 6789:2017 standards and includes a certificate for traceability.

Pros

High accuracy supports critical applications.

Wide selection of drive sizes and torque ranges.

Ergonomic bi-material handle reduces hand fatigue.

Quick-release ratchet head speeds up socket changes.

Dual scale (ft-lb and Nm) increases versatility.

Durable construction withstands heavy use.

Calibration certificate included for quality assurance.

Cons

Premium pricing may not suit all budgets.

Some models feel heavier than competitors.

Digital models require batteries and periodic recalibration.

Limited availability in some regions.

Unique Features

FACOM stands out for its focus on ergonomics and durability. The bi-material handle provides a secure, comfortable grip, even in oily environments. The quick-release ratchet head allows for rapid socket changes, improving workflow efficiency. FACOM’s commitment to quality shows in its rigorous calibration process and robust construction. Professionals who demand reliability and comfort often select FACOM for daily use.

Tip: FACOM torque wrenches excel in environments where both precision and user comfort are essential.

DeWALT

Specs

| Specification | Details / Examples |

| Accuracy | ±4% clockwise, ±6% counterclockwise |

| Torque Range | 10–250 ft-lb (varies by model) |

| Drive Size | 1/2 inch, 3/8 inch |

| Type of Torque Wrench | Click-type, digital |

| Calibration Standards | Factory calibrated, ISO 6789 compliant |

| Ergonomic Features | Rubberized grip, lightweight body |

| Additional Features | Audible click, LED indicator (digital), storage case |

DeWALT torque wrenches combine rugged construction with user-friendly features. The brand offers both click-type and digital models, each designed for professional use in automotive and construction settings. DeWALT wrenches arrive factory-calibrated and ready for immediate use.

Pros

Reliable torque delivery for a variety of tasks.

Lightweight design reduces user fatigue.

Rubberized grip ensures comfort and control.

Audible click or LED indicator signals correct torque.

Storage case protects the tool during transport.

Good value for the feature set.

Cons

Slightly lower accuracy than some premium brands.

Digital models require batteries and regular calibration.

Fewer drive size options compared to competitors.

Some users report the click is less pronounced at low torque.

Unique Features

DeWALT torque wrenches feature a rugged, lightweight body that stands up to tough jobsite conditions. The rubberized grip enhances comfort during extended use. Digital models include an LED indicator for clear feedback. DeWALT’s focus on practical features and durability makes these wrenches a popular choice for professionals who need dependable tools at a reasonable price.

Note: DeWALT wrenches offer a strong balance of performance and affordability, making them ideal for busy shops and fieldwork.

KNIPEX

Specs

| Specification | Details / Examples |

| Accuracy | ±3% clockwise, ±6% counterclockwise |

| Torque Range | 10–150 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch |

| Type of Torque Wrench | Click-type, digital |

| Calibration Standards | ISO 6789:2017, supplied with calibration certificate |

| Ergonomic Features | Slim handle, anti-slip coating |

| Additional Features | Audible click, dual scale, compact storage case |

KNIPEX torque wrenches deliver precision and reliability for professionals in mechanical, electrical, and industrial fields. The brand offers both click-type and digital models, each calibrated to ISO 6789:2017 standards.

Pros

High accuracy supports demanding applications.

Slim, anti-slip handle improves control in tight spaces.

Dual scale (ft-lb and Nm) enhances versatility.

Compact storage case included.

Durable construction ensures long service life.

Calibration certificate provides confidence in measurements.

Cons

Premium price reflects advanced features.

Limited torque range compared to some competitors.

Digital models require batteries and periodic recalibration.

Availability may vary by region.

Unique Features

KNIPEX stands out for its slim, ergonomic handle and anti-slip coating. These features allow technicians to work comfortably in confined areas. The compact storage case protects the tool and makes transport easy. KNIPEX’s commitment to precision and quality appeals to professionals who require consistent, reliable torque application.

Professionals who value comfort, precision, and durability often choose KNIPEX for their daily torque needs.

STAHLWILLE

Specs

| Specification | Details / Examples |

| Accuracy | ±2% clockwise, ±3% counterclockwise |

| Torque Range | 10–400 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch |

| Type of Torque Wrench | Click-type, electronic, dial |

| Calibration Standards | ISO 6789:2017, supplied with calibration certificate |

| Ergonomic Features | Slim handle, anti-slip grip, lightweight design |

| Additional Features | Quick-release ratchet, dual scale, memory function (digital) |

STAHLWILLE torque wrenches deliver high precision and robust engineering. The brand offers a wide range of models, including click-type, electronic, and dial indicating wrenches. Each tool arrives calibrated to ISO 6789:2017 standards and includes a certificate for traceability.

Pros

High accuracy supports critical applications in automotive, aerospace, and industrial sectors.

Lightweight and slim design improves handling in tight spaces.

Durable construction ensures long service life, even under heavy use.

Quick-release ratchet head speeds up socket changes.

Dual scale (ft-lb and Nm) increases versatility for international work.

Electronic models feature memory functions for repetitive tasks.

Calibration certificate included for quality assurance.

Cons

Premium pricing may not fit all budgets.

Some models feel heavier than competitors in the same class.

Digital and electronic models require batteries and periodic recalibration.

Limited availability in some regions outside Europe.

Unique Features

STAHLWILLE stands out for its focus on precision engineering and ergonomic design. The anti-slip grip and lightweight body allow technicians to work comfortably for extended periods. Electronic models offer memory storage, which streamlines repetitive torque applications. The quick-release ratchet head and dual scale markings enhance workflow efficiency. STAHLWILLE’s commitment to quality and innovation makes it a top choice for professionals who demand reliability and accuracy.

Tip: Professionals who need a torque wrench for demanding, high-precision work often select STAHLWILLE for its proven track record and advanced features.

BETA

Specs

| Specification | Details / Examples |

| Accuracy | ±3% clockwise, ±5% counterclockwise |

| Torque Range | 10–300 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch |

| Type of Torque Wrench | Click-type, digital |

| Calibration Standards | ISO 6789:2017, supplied with calibration certificate |

| Ergonomic Features | Bi-material handle, anti-slip surface |

| Additional Features | Audible click, dual scale, compact storage case |

BETA torque wrenches combine Italian craftsmanship with reliable performance. The brand offers both click-type and digital models, each designed for professional use in automotive and industrial environments.

Pros

Consistent accuracy meets industry standards for professional applications.

Bi-material handle provides a comfortable, secure grip.

Audible click ensures precise torque application.

Dual scale (ft-lb and Nm) supports a wide range of tasks.

Compact storage case protects the tool during transport.

Calibration certificate included for traceability.

Cons

Slightly lower accuracy than some German-engineered brands.

Digital models require batteries and regular calibration.

Limited torque range compared to some competitors.

Availability may vary by region.

Unique Features

BETA distinguishes itself with its ergonomic bi-material handle and compact design. The audible click and clear scale markings help users achieve precise torque settings. The storage case adds value for professionals who travel between job sites. BETA’s focus on comfort and reliability appeals to technicians who need a dependable tool for daily use.

Note: BETA torque wrenches offer a strong balance of comfort, accuracy, and value, making them a practical choice for busy professionals.

HAZET

Specs

| Specification | Details / Examples |

| Accuracy | ±2% clockwise, ±3% counterclockwise |

| Torque Range | 10–600 ft-lb (varies by model) |

| Drive Size | 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch |

| Type of Torque Wrench | Click-type, electronic, dial |

| Calibration Standards | ISO 6789:2017, supplied with calibration certificate |

| Ergonomic Features | Slim handle, anti-slip grip, robust construction |

| Additional Features | Quick-release ratchet, dual scale, memory function (digital) |

HAZET torque wrenches represent German engineering at its finest. The brand produces a broad range of click-type, electronic, and dial indicating models, each designed for professional use in demanding environments.

Pros

Exceptional accuracy supports critical torque applications.

Wide torque range covers everything from light assembly to heavy machinery.

Robust construction withstands harsh working conditions.

Slim, anti-slip handle improves control and comfort.

Quick-release ratchet head enhances workflow efficiency.

Dual scale (ft-lb and Nm) increases versatility.

Calibration certificate included for quality assurance.

Cons

Premium price reflects advanced engineering and features.

Digital and electronic models require batteries and periodic recalibration.

Some models may feel heavier than basic click-type wrenches.

Availability may be limited outside Europe.

Unique Features

HAZET stands out for its robust build and advanced features. The slim, anti-slip handle allows for precise control, even in challenging environments. Electronic models offer memory storage and real-time torque feedback. The quick-release ratchet head and dual scale markings support efficient, accurate work. HAZET’s reputation for durability and precision makes it a preferred choice for professionals who require the highest standards.

Professionals who demand uncompromising accuracy and reliability often choose HAZET for their most critical torque applications.

Comparison Table

Specs Overview

Professionals compare torque wrenches by examining specifications such as drive size, torque range, accuracy, and type. The following table presents a quick reference for leading models, including the recommended Newstar Hardware brand. Each wrench offers a unique torque scale, supporting a variety of applications from automotive to industrial work.

| Brand/Model | Drive Size | Torque Range (English) | Torque Range (Metric) | Type | Accuracy |

| Newstar Hardware | 1/4", 3/8", 1/2" | 10–150 ft-lbf / 20–150 in-lbf | 2.8–15.3 N·m / 47–332 N·m | Click-type | ±3% |

| Tekton Click | 1/2", 3/8", 1/4" | 10–150 ft-lbf | 13.6–203 N·m | Click-type | ±4% CW, ±6% CCW |

| ACDelco Digital | 1/2", 3/8" | 4–99 ft-lbf | 5.4–134 N·m | Digital | ±2% CW, ±3% CCW |

| Precision Instruments | 3/8", 1/2" | 40–250 ft-lbf | 54–339 N·m | Split Beam | ±4% CW |

| Snap-On | 1/4", 3/8", 1/2" | 5–250 ft-lbf | 6.8–339 N·m | Click/Digital/Split | ±3% CW, ±6% CCW |

| MAC | 1/4", 3/8", 1/2" | 10–250 ft-lbf | 13.6–339 N·m | Click/Digital | ±4% CW, ±6% CCW |

| Harbor Freight | 1/2", 3/8", 1/4" | 20–150 ft-lbf | 27–203 N·m | Click-type | ±4% CW, ±6% CCW |

| SVOPES | 1/2", 3/8" | 10–150 ft-lbf | 13.6–203 N·m | Click/Digital | ±3% CW, ±5% CCW |

| Norbar | 1/4", 3/8", 1/2", 3/4" | 10–330 ft-lbf | 13.6–447 N·m | Click/Digital/Dial | ±1% CW, ±2% CCW |

| FACOM | 1/4", 3/8", 1/2", 3/4" | 10–340 ft-lbf | 13.6–461 N·m | Click/Digital/Dial | ±3% CW, ±6% CCW |

| DeWALT | 1/2", 3/8" | 10–250 ft-lbf | 13.6–339 N·m | Click/Digital | ±4% CW, ±6% CCW |

| KNIPEX | 1/4", 3/8", 1/2" | 10–150 ft-lbf | 13.6–203 N·m | Click/Digital | ±3% CW, ±6% CCW |

| STAHLWILLE | 1/4", 3/8", 1/2", 3/4" | 10–400 ft-lbf | 13.6–542 N·m | Click/Electronic/Dial | ±2% CW, ±3% CCW |

| BETA | 1/4", 3/8", 1/2" | 10–300 ft-lbf | 13.6–407 N·m | Click/Digital | ±3% CW, ±5% CCW |

| HAZET | 1/4", 3/8", 1/2", 3/4" | 10–600 ft-lbf | 13.6–813 N·m | Click/Electronic/Dial | ±2% CW, ±3% CCW |

Price and Warranty

Cost and warranty terms play a major role in the selection process. Most torque wrenches in this comparison offer a one-year limited manufacturer’s warranty. The price varies by model, torque range, and features. For example, the 2503MFRMH model lists at CAD 299.00. Other models do not display price information, but professionals expect higher cost for advanced digital wrenches or those with extended torque range. Consistent warranty coverage ensures peace of mind for users who rely on their wrench daily.

| Model Code | Drive Size | Torque Range (English) | Warranty | Price (CAD) |

| 2503MFRMH | N/A | 30 to 250 ft-lbf | 1 year limited manufacturer’s warranty | 299.00 |

| 501MRMH | 1/4" | 10 to 50 in-lbf | 1 year limited manufacturer’s warranty | N/A |

| 752MFRMH | 3/8" | 5 to 75 ft-lbf | 1 year limited manufacturer’s warranty | N/A |

Professionals should review warranty terms and cost before purchasing. A higher cost often reflects advanced features, broader torque range, or improved durability.

Key Features

Professionals prioritize several features when comparing torque wrenches. A wide torque range allows the wrench to handle diverse tasks. High accuracy ensures precise torque application. Durability supports long-term use in demanding environments. Drive size affects compatibility with different fasteners. Calibration certificates confirm reliability. Ease of use, such as ergonomic grip and clear torque scale, improves workflow. Feedback mechanisms, including audible clicks or digital displays, help users apply the correct torque. Some digital wrenches offer datalink capabilities for traceability.

| Feature | Description |

| Torque Range | Covers applications from automotive to industrial projects. |

| Accuracy | Delivers precise torque as specified for each job. |

| Durability | Withstands heavy use and maintains calibration. |

| Drive Size | Matches fastener size for optimal torque transfer. |

| Calibration | Includes certificate; regular calibration maintains accuracy. |

| Ease of Use | Ergonomic grip and clear torque scale support efficient operation. |

| Feedback Mechanisms | Audible click, digital display, or visual indicator confirms correct torque application. |

| Type | Click, digital, split beam, or dial; each type offers unique benefits. |

| Additional Features | Advanced models may include software integration or exchangeable heads for flexibility. |

Selecting the right torque wrench depends on matching torque range, accuracy, and key features to the intended application. Professionals should consider cost, warranty, and usability before making a decision.

Choosing the Right Torque Wrench

![Choosing the Right Torque Wrench]()

Professional Use Cases

Professionals select torque wrenches based on the demands of their field. Automotive technicians often rely on click torque wrenches with torque ranges designed for tightening engine components and lug nuts. Aerospace engineers require electronic torque wrenches for precise control during assembly. Industrial mechanics choose models built for thousands of tightening cycles, such as the KS TOOLS 516.5062, which offers reliable torque release accuracy. Compact torque wrenches serve motorcycle and bicycle technicians who need tools with specific drive sizes for tire pressure control systems. Aviation and industrial sectors benefit from wrenches like the Beta 666N, which features enhanced scale visibility and chemical resistance. Each profession demands a torque wrench that matches its unique requirements for safety, accuracy, and efficiency.

Automotive: Click-type, mid-range torque, 1/2" drive.

Aerospace: Electronic, high precision, multiple drive sizes.

Industrial: Heavy-duty, split beam, extended cycle life.

Motorcycle/Bicycle: Compact torque wrenches, reversible ratchet, low torque range.

Professionals improve workflow and reduce errors by choosing torque wrenches tailored to their specific use cases.

Budget Considerations

Cost plays a significant role in the selection process. Professionals must balance performance with affordability. Entry-level models offer great value for routine tasks, while advanced digital wrenches command a higher cost due to added features. Compact torque wrenches often provide great value for technicians who need portability without sacrificing accuracy. Many brands, including Newstar Hardware, deliver great value by combining reliability and cost-effective pricing.

| Type | Typical Cost (USD) | Great Value For |

| Click-Type | $50–$200 | Automotive, general repair |

| Digital | $150–$600 | Aerospace, quality control |

| Split Beam | $200–$500 | Industrial, heavy machinery |

| Compact Torque Wrenches | $60–$250 | Motorcycle, bicycle, fieldwork |

Technicians often compare cost against warranty coverage and expected lifespan. A higher initial cost may result in lower maintenance expenses and longer service intervals. Great value emerges when a torque wrench maintains calibration and delivers consistent results over time. Professionals should assess whether the cost aligns with the frequency and criticality of their tasks.

Choosing a torque wrench with great value ensures professionals maximize their investment and minimize long-term costs.

Must-Have Features

Professionals prioritize features that enhance accuracy, durability, and ease of use. Compact torque wrenches offer portability for fieldwork and tight spaces. An easy-to-read scale and audible feedback help prevent over-tightening. Models with reversible ratchet heads increase versatility. Calibration certificates provide assurance of accuracy. Ergonomic handles reduce fatigue during extended use. Many technicians seek great value in wrenches that combine these features with a reasonable cost.

Portability: Compact torque wrenches fit into toolkits and travel cases.

Feedback: Audible click or digital alerts confirm correct torque.

Versatility: Multiple drive sizes and torque ranges suit diverse tasks.

Durability: Hardened steel construction withstands heavy use.

Calibration: Certificate included for traceability and confidence.

Ergonomics: Comfortable grip supports long work sessions.

Professionals achieve great value by selecting torque wrenches that deliver essential features at a manageable cost.

Maintenance Tips

Proper maintenance ensures that a professional lbf torque wrench delivers accurate results and lasts for years. Technicians who follow best practices protect their investment and maintain safety standards on every job. The following steps help extend the lifespan and reliability of any torque wrench:

Clean and Lubricate Regularly

Technicians should wipe down the wrench after each use. Removing dirt and debris prevents rust and corrosion. Light lubrication of moving parts keeps the mechanism smooth and responsive.

Protect from Moisture

Storing the wrench in a dry environment prevents rust. Moisture can damage internal components and compromise accuracy. Many professionals use a dedicated case or tool chest with desiccant packs for added protection.

Set Preload for Click-Type Wrenches

When not in use, set the preload to 20% or less of the maximum torque value. This practice prevents permanent spring compression, which can affect calibration.

Reset to Lowest Value After Use

After completing a task, always return the torque scale to its lowest setting. This step helps maintain the accuracy of the internal spring and extends the tool’s service life.

Schedule Regular Calibration

Frequent users should recalibrate their torque wrenches two to three times per year. Calibration ensures that the tool meets industry standards and delivers precise torque readings. If the wrench is dropped, immediate recalibration is necessary to verify accuracy.

Avoid Improper Use

Professionals should never use a torque wrench to loosen bolts or retighten fasteners previously tightened with standard tools. This misuse can damage the internal mechanism and lead to inaccurate readings.

Tip: Many leading brands, such as Newstar Hardware, recommend following these maintenance steps to preserve warranty coverage and ensure optimal performance.

A well-maintained torque wrench supports consistent, safe work in automotive, industrial, and aerospace settings. By following these simple guidelines, technicians can trust their tools to deliver reliable results on every project. Regular care not only extends the lifespan of the wrench but also upholds the standards required in professional environments.

Professionals seeking the best lbf torque wrench should review the comparison table and buying guide for quick, informed decisions. Newstar Hardware stands out as a top recommendation for accuracy and durability. Each professional must match the wrench to specific job needs and budget. For those ready to purchase, visiting trusted brand sites and reviewing warranty details ensures a smart investment.

FAQ

What does "lbf" mean in torque wrenches?

"Lbf" stands for pound-force. It measures the force applied to a fastener. Professionals use lbf to specify torque settings for accuracy in mechanical work.

How often should a torque wrench be calibrated?

Technicians calibrate torque wrenches every 6 to 12 months. Heavy use or accidental drops require immediate calibration. Regular calibration maintains accuracy and tool reliability.

Can a torque wrench be used to loosen bolts?

Manufacturers advise against using torque wrenches to loosen bolts. This practice can damage the internal mechanism and affect future accuracy.

What is the difference between click-type and digital torque wrenches?

Click-type wrenches provide a physical "click" at the set torque. Digital models display torque values and offer alerts. Digital wrenches often include advanced features for data tracking.

Which brand offers the best warranty for professionals?

Newstar Hardware provides an excellent warranty and responsive support. Many professionals recommend this brand for reliability and service.

How do technicians choose the correct drive size?

Technicians select drive size based on the fastener and application. Common sizes include 1/4", 3/8", and 1/2". Larger drive sizes suit heavy-duty tasks.

What maintenance steps extend the life of a torque wrench?

Clean after each use. Store in a dry case. Set to the lowest torque value before storage. Schedule regular calibration. Avoid using the wrench for loosening bolts.

Are torque wrenches suitable for all industries?

Torque wrenches serve automotive, aerospace, industrial, and construction sectors. Professionals select models based on required torque range, accuracy, and durability.