![How Torque Wrenches Measure Pound-Force Explained Simply]()

Picture this: you grab a torque wrench to tighten the lug nuts on your car’s wheel. You want the job done right, so you need the correct torque. The wrench measures how much force you apply at a certain distance. In this case, the unit is pound-force. Every torque wrench helps you avoid over-tightening or under-tightening. When you see torque wrenches pound force on the tool, you know exactly how much pressure to use. A good wrench gives you confidence on every project.

Pound-Force in Torque Wrenches

What Is Pound-Force?

When you use a torque wrench, you measure how much twisting force you apply to a bolt or nut. This force is called torque. In the United States, you often see torque measured in pound-force feet (lb·ft or lbf·ft). Pound-force means the force of one pound acting at a right angle to a lever that is one foot long. For example, if you push down with one pound of force at the end of a one-foot wrench, you create one pound-foot of torque. This matches the engineering formula:

Torque = Force × Distance

So, if you use a three-foot wrench and push with 15 pounds of force, you get 45 pound-feet of torque. The Society of Automotive Engineers (SAE) sets this standard for measuring torque in cars and other machines. You will see this unit on most torque wrenches pound force scales.

Pound-Force vs. Other Units

You may notice other units on some wrenches, such as newton-meters (N·m) or kilogram-force meters (kgf·m). These units come from different measurement systems. Newton-meters are the standard unit in the metric system. They measure force in newtons and distance in meters. Kilogram-force meters use the weight of one kilogram under gravity.

Here is a quick comparison:

| Unit | System | Force Unit | Distance Unit | Common Use |

| Pound-force foot | Imperial | Pound-force | Foot | US, UK, SAE tools |

| Newton-meter | Metric (SI) | Newton | Meter | Europe, Asia |

| Kilogram-force meter | Metric | Kilogram-force | Meter | Some Asian regions |

One pound-foot equals about 1.36 newton-meters. If you use the wrong unit, you risk applying too much or too little torque. This can damage threads, break bolts, or cause parts to come loose.

Why Pound-Force Matters

Using the correct unit on your torque wrench keeps your work safe and accurate. If you set your wrench to newton-meters instead of pound-force, you might over-tighten or under-tighten bolts. This can lead to:

Damaged threads or broken bolts

Loose joints or leaks

Equipment failure and costly repairs

Safety hazards for you and others

Always check the unit on your torque wrench before you start. Matching the unit to your project instructions helps you avoid mistakes.

You will also see torque wrenches pound force marked in foot-pounds or inch-pounds. Foot-pounds (lb·ft) use feet for the lever length, while inch-pounds (lb·in) use inches. For smaller fasteners, inch-pounds give you more precise control. For larger bolts, foot-pounds are standard.

When you understand these units, you can use your wrench with confidence and keep your projects safe.

Torque Wrenches Pound Force Measurement

Torque = Force x Length

You use a torque wrench to apply a twisting force to a bolt or nut. The basic formula for torque is:

Torque = Force × Length

Force means how hard you push or pull. Length is the distance from the center of the bolt to where you grip the wrench. In most cases, you hold the wrench so your force is at a right angle to the handle. This makes the math simple. For example, if you push with 10 pounds of force at the end of a 2-foot wrench, you create 20 pound-feet of torque.

You see this formula in action every time you tighten a car wheel or assemble furniture. Mechanics use torque wrenches pound force to make sure bolts are tight enough but not too tight. In sports, athletes use torque to swing bats or clubs. In robotics, motors use torque to move arms and joints. The formula helps you understand how both force and handle length affect the result.

Tip: Always apply force at the end of the wrench handle. This gives you the correct torque and keeps your measurement accurate.

How Torque Wrenches Measure

A torque wrench measures force at a set distance from the bolt. When you pull on the handle, the wrench senses how much twisting force you create. Some wrenches, like beam types, bend a metal bar and show the reading on a scale. Others, like click wrenches, use a spring that "clicks" when you reach the set torque.

Handle length matters. If you grip the wrench closer to the head, you shorten the lever arm. This can double the torque you apply without changing the reading. Always hold the wrench at the handle end, unless the instructions say otherwise. Some torque wrenches are length-dependent, so your hand position changes the torque output. Others are length-independent and give the same reading no matter where you hold them.

If you add an extension to the wrench, you increase the total length. This means you apply more torque than the wrench shows. For example, if you use a pipe to extend the handle, you might over-tighten the bolt. The wrench measures torque at its own length, not with the extension. Always check if your tool and setup match the instructions for your project.

Calibration keeps your torque wrench accurate. Over time, parts wear out and readings can drift. Calibration uses special equipment and follows standards like ISO 6789 or NIST. Certified labs test the wrench and adjust it if needed. Companies with many torque wrenches pound force often set up their own labs to keep tools in top shape. Regular calibration prevents mistakes and keeps your work safe.

Note: Calibration certificates show the date, error range, and lab details. Check your wrench's calibration before starting important jobs.

Displaying Pound-Force

Torque wrenches show pound-force in different ways. Beam-type wrenches have a pointer and a scale, usually marked in 5 or 10 ft-lb steps. This means you can read the torque to the nearest 2.5 or 5 ft-lb. Click wrenches have a dial or window where you set the desired torque. Digital wrenches use a screen to show the exact value, often down to decimal points.

Beam-type wrenches: Scale graduations in 5 or 10 ft-lb increments. Practical accuracy is about half the increment size.

Click and digital wrenches: Finer graduations, often 1 ft-lb or less. Digital models give the best resolution.

Digital displays: Show real-time torque values, even in low light. Some models beep, flash, or vibrate when you reach the target.

Digital torque wrenches pound force make it easy to switch between units, like foot-pounds and inch-pounds. They also help prevent over-tightening or under-tightening by giving clear feedback. You can trust the reading, even in dim garages or tight spaces.

Pro Tip: Use a digital torque wrench for jobs that need high precision. The clear display and alerts help you avoid mistakes.

Types of Torque Wrenches

![Types of Torque Wrenches]()

Beam Torque Wrenches

You will find beam torque wrenches simple and reliable. This type uses two rods: one bends as you apply force, and the other stays straight with a scale. You read the torque by looking at the pointer’s position on the scale. Most beam wrenches show pound-force in either inch-pounds or foot-pounds. You do not hear a sound or feel a click; you must watch the scale closely. Beam wrenches hold their calibration well and rarely need adjustment. You can trust their accuracy if you read the scale straight on. Hand placement does not affect the measurement much because of the design. These wrenches work best for non-critical jobs, like tightening lug nuts or assembling furniture.

Tip: Always read the scale from directly above to avoid errors of 5 to 10 pound-force.

Click Torque Wrenches

Click torque wrenches are popular for automotive and mechanical work. You set the desired torque by turning the handle. As you apply force, the wrench uses a clutch mechanism. When you reach the preset value, you hear and feel a click. This signal tells you to stop turning. Click wrenches measure pound-force in inch-pounds or foot-pounds, depending on the model. You get audible and tactile feedback, which helps you avoid over-tightening. These wrenches need regular calibration and maintenance to keep their accuracy. You must reset the wrench to zero after each use to prolong its life. Hand placement can affect the reading by up to 10 pounds, so always grip the handle as instructed.

Click wrenches offer good precision for most tasks.

They are compact and easy to use.

You should calibrate them yearly for best results.

| Torque Wrench Type | Accuracy Characteristics | Precision Notes | Calibration & Usage Considerations | Cost & Practicality |

| Beam | Reliable if read correctly | Consistent; needs straight-on reading | Rarely needs calibration | Affordable, durable |

| Click | Accurate; depends on quality | Good precision; tactile feedback | Needs resetting and calibration | Moderate cost |

| Electronic | Very precise; digital readout | High precision | Calibration varies | Higher cost |

Electronic Torque Wrenches

Electronic torque wrenches use sensors and processors to measure torque. You see the value on a digital display, often in pound-force units. Many models beep, flash, or vibrate when you reach the target torque. You can switch between inch-pounds and foot-pounds easily. Electronic wrenches offer high precision and are user-friendly. You get real-time feedback, which helps you avoid mistakes. These wrenches cost more than beam or click types, but they provide the best accuracy. You should calibrate them as recommended by the manufacturer. Electronic wrenches work well for jobs that demand exact torque, such as engine assembly or aerospace work.

Note: Use electronic wrenches for tasks that require the highest precision and accuracy.

You should use any torque wrench within 20% to 90% of its maximum range for best accuracy. All types have error margins, but electronic wrenches usually stay within 2%. Click wrenches have about 4% error, and beam wrenches are less precise but very reliable for everyday use.

How to Use a Torque Wrench

![How to Use a Torque Wrench]()

Setting Pound-Force

Setting the correct pound-force on your torque wrench ensures you tighten bolts to the right specification. Follow these steps for click and electronic models:

Find the required torque value and unit for your task, such as lb-ft.

Make sure your wrench displays the correct unit.

For a click torque wrench, twist the handle until the indicator lines up with your target value. For a digital model, turn it on and set the desired value using the buttons.

Attach the right socket to the wrench.

Place the socket on the fastener.

Tighten the fastener. Stop when you hear a click (for click wrenches) or see/hear an alert (for digital wrenches).

Remove the socket from the fastener.

Tip: Always double-check the unit before you start. Mixing up units can lead to over-tightening or under-tightening.

Reading the Scale

Reading the scale on your torque wrench correctly is key to accurate results. Here’s how you do it:

Set the scale by looking straight at it. Avoid viewing from an angle, which can cause errors.

Turn the wrench slowly and steadily. Stop as soon as you hear or feel the click or see the digital alert.

Hold the wrench only by the handle. The tool is calibrated for force applied at this spot.

Use any markings or grooves on the handle as a guide for your grip.

Note: Proper hand placement keeps your readings accurate and prevents tool damage.

Common Mistakes

Many users make simple errors when learning how to use a torque wrench. Watch out for these common mistakes:

Using the wrench to loosen bolts. This can damage the tool.

Confusing units like ft-lb and N-m, which leads to incorrect settings.

Operating the wrench at its highest or lowest range, which reduces accuracy.

Using the wrench beyond its rated capacity.

Skipping regular calibration or not checking accuracy.

Storing the wrench without resetting it to the lowest setting.

Using the wrench as a breaker bar or with extra pipes.

Gripping the wrench incorrectly or applying uneven force.

Failing to recalibrate after dropping the wrench.

Forgetting that electronic wrenches also need proper use and calibration.

Always treat your torque wrench with care. Store it properly and check calibration often for the best results.

A torque wrench is a precision tool. Learning how to use a torque wrench the right way helps you avoid costly mistakes and keeps your projects safe.

Ensuring Accurate Torque

Calibration

You keep your torque wrench accurate by following a regular calibration schedule. Calibration checks and adjusts your tool so it delivers the correct force every time. Industry standards like ISO 6789 recommend calibrating your wrench every 12 months or after 5,000 uses, whichever comes first. If you use your wrench often or for high-precision jobs, you should calibrate it even more frequently—every 2,500 to 3,000 uses. Calibration becomes urgent if you overload the wrench, drop it, or send it for repairs. Always store your wrench at its minimum setting to help preserve accuracy between calibrations.

Tip: Calibration involves testing your wrench at several points across its range and adjusting it to keep errors within about ±4% for most mechanical models.

Proper Technique

Using the right technique ensures you achieve proper torque and repeatable results. Start by setting your wrench to the recommended value and locking it in place. Attach the correct socket and center your hand on the handle. Pull the wrench smoothly and steadily, aiming for a consistent speed. Too fast or too slow can change the force you apply. Always pull rather than push for better control. Stop as soon as you hear the click or see the digital alert—never double-click or overpull. Use only attachments that line up with the wrench head, and avoid handle extensions.

| Best Practice Aspect | Key Recommendations |

| Hand Placement | Always pull at the handle area; use your other hand to steady the head. |

| Wrench Speed | Keep a steady pace—about 22.5° per second. |

| Consistent Technique | Pull, don’t push; stop at the signal. |

| Overpull | Never go past the target; avoid double-clicking. |

| Attachments | Use only approved adapters; never use cheater bars. |

Note: Consistent technique helps you achieve the same results every time, which is vital for safety and performance.

Maintenance Tips

Good maintenance keeps your torque wrench reliable and extends its life. After each use, reset the wrench to its lowest setting to protect the internal spring. Clean the tool with a soft cloth and mild cleaner to remove dirt and grease. Store your wrench in its case, away from moisture and extreme temperatures. Regularly inspect for damage, smooth operation, and worn parts. Lubricate moving parts as the manufacturer suggests. Never use your wrench as a breaker bar or for loosening bolts. If you drop the tool or suspect a problem, schedule a calibration check right away.

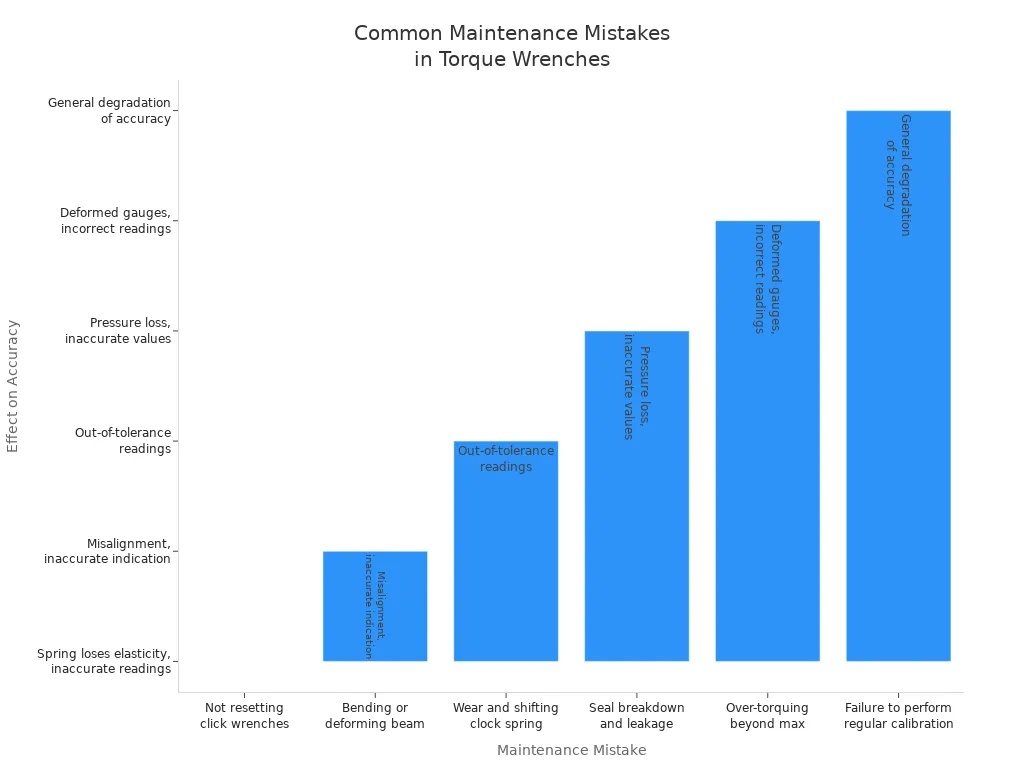

![Bar chart showing maintenance mistakes and their impact on torque wrench accuracy]()

Common mistakes—like not resetting the wrench, over-tightening, or skipping calibration—lead to inaccurate readings. Protect your investment by following these simple steps:

Store in a dry, clean case.

Avoid impacts and bending.

Clean and lubricate regularly.

Calibrate at least once a year or after 5,000 uses.

Keeping up with calibration and maintenance ensures your wrench delivers precision and proper torque every time you use it.

Real-World Uses for Torque Wrenches

Automotive

You rely on a torque wrench every time you work on your car. Mechanics use this tool to tighten bolts on critical parts such as engine blocks, cylinder heads, and suspension systems. If you apply too much force, you risk damaging threads or breaking bolts. Too little force can cause leaks or loose components. For example, axle bolts, hub bolts, and trailer hitch bolts require precise torque between 50 and 250 ft-lbs. Driveline components and transfer cases need even higher torque, sometimes up to 600 ft-lbs. Racing vehicles and camshaft sprockets may demand torque over 1,000 ft-lbs. Different types of wrenches help you meet these needs. Click wrenches cover a wide range and suit most automotive tasks. Break-over wrenches fit tight spaces and offer more precision. Cam-over wrenches work best for zero-error jobs like internal engine fasteners. Pulse wrenches deliver high torque quickly for large bolts.

| Torque Range (ft.lbs) | Common Automotive Applications | Importance of Precision |

| 50 - 250 | Axle bolts, hub bolts, trailer hitch bolts | Critical applications within moderate duty |

| 120 - 600 | Driveline components, bearings, transfer cases, differentials | Heavy duty fasteners requiring precise torque |

| 200 - 1000+ | Camshaft sprockets, harmonic balancers, off-road and performance racing vehicles | Very heavy duty fasteners with high torque needs |

You protect your car and your safety by using the correct pound-force setting on your wrench. Always check the specifications before you start.

Home Projects

You use a torque wrench for more than just cars. Home improvement projects often require precise torque to keep parts secure and prevent damage. When you assemble furniture, install a deck, or mount a TV bracket, you need to tighten bolts to the manufacturer’s recommended value. Digital wrenches help you avoid overtightening by alerting you with a beep or vibration. This feature keeps your work safe and prevents stripped threads. If you drop your wrench, recalibrate it before your next project. Reset the torque setting before storing the tool to maintain accuracy. Applying the correct pound-force ensures that parts stay together without breaking or failing. Certified wrenches help you meet safety standards and avoid costly mistakes.

Tip: Always use a calibrated torque wrench for tasks like mounting shelves, assembling playground equipment, or installing bike racks. You reduce the risk of accidents and keep your home safe.

Safety

Safety depends on proper torque application in many situations. If you use the wrong pound-force setting, you risk mechanical failure or even injury. For example, an amusement park ride failed when improper torque caused a lock washer to shear off, leading to a dangerous breakdown. In another case, an e-bike recall traced the problem to incorrect torque on the fork steerer tube, which led to material fatigue and failure. Even in manufacturing, vulnerabilities in smart wrenches can allow undetected changes to torque settings, causing loose connections and fire hazards. You avoid these risks by following manufacturer instructions and using a properly calibrated wrench. Always check your settings and recalibrate your tool after any impact. You protect yourself and others by making sure every bolt is tightened to the correct specification.

Note: Using a torque wrench with the right pound-force setting helps you prevent accidents, equipment damage, and costly repairs. Your attention to detail keeps every project safe.

You now know how torque wrenches measure pound-force and why accuracy matters. Always choose the right wrench for your job and keep it calibrated. Remember to use your wrench only for final tightening and avoid working at the lowest end of its range. Clean threads and proper lubrication help you get reliable results. ️ For best accuracy, operate near the middle of your wrench’s range and check for a clear “click” or reading. Regular care keeps your projects safe and your tools precise.

FAQ

What is the difference between foot-pounds and inch-pounds?

Foot-pounds measure torque using feet as the lever length. Inch-pounds use inches. One foot-pound equals 12 inch-pounds. Use foot-pounds for larger bolts and inch-pounds for smaller fasteners.

How often should you calibrate your torque wrench?

You should calibrate your torque wrench every 12 months or after 5,000 uses. If you drop the wrench or use it for critical work, calibrate it sooner.

Can you use a torque wrench to loosen bolts?

No, you should not use a torque wrench to loosen bolts. This can damage the tool and affect its accuracy. Use a standard wrench for loosening.

What happens if you over-tighten a bolt?

Over-tightening can strip threads, break bolts, or damage parts. Always follow the recommended pound-force setting to keep your work safe and reliable.

How do you store a torque wrench?

Store your torque wrench in its case, set to the lowest setting. Keep it in a dry place. This protects the internal spring and keeps the tool accurate.

Why does hand placement matter when using a torque wrench?

Hand placement affects the force you apply. Always grip the handle where the manufacturer recommends. This ensures you get the correct torque reading.

Can you use adapters or extensions with a torque wrench?

Use adapters or extensions only if necessary. They can change the torque applied. Always check your wrench’s manual for guidance and adjust your technique if needed.

What should you do if your torque wrench gets wet or dirty?

Clean your wrench with a soft cloth. Dry it completely before storing. Moisture and dirt can cause rust or affect the tool’s accuracy.